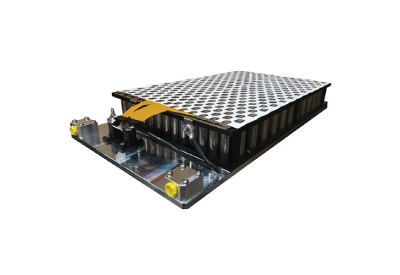

Mersen Introduce Infini-Cell Battery Assembly Solution

Sept 21, 2020

Mersen and F & K DELVOTEC have joined forces to create the optimum battery assembly solution to support 21700 series battery assembly systems.

As e-mobility and battery energy storage applications grow in number and power density, designers are looking to reduce the footprint of the battery assemblies without compromising efficiency or modularity of their power systems. Customers are looking to component manufacturers to create standardized battery assemblies that benefit from the latest technologies available to produce a leading $/KW and kWh/Kg on a modular and flexible platform. Designers want the best of both worlds, being high efficiency and high flexibility, in sourcing their battery assembly solutions for their applications.

Unlike traditional battery interconnect solutions, the F & K DELVOTEC laser bonder interface guarantees a high speed, safe, robust, and efficient connection of the battery cells to the laminated bus bar. This method is more than four times faster than conventional wire / ribbon insertion and welding. The laminated bus bar is an ultra-thin single layer with interleaved contacts. The bus bar is also a “smart” bus bar; it not only powers the battery cells but also monitors temperature and voltage of battery cells as needed. Bus bars also eliminate wiring error and provide an extra degree of robustness against shock and vibration in e-mobility installations. To protect the battery assembly from over currents, a special low watt loss/ high cycling DC rated fuse is installed. The battery assembly is then secured onto a super compact (only 7mm thick) liquid cooled cold plate, providing a homogenous cooling to all battery cells.

Go HERE for more information