Secondary Network Arc Flash Case Study

Aug 18, 2019

By Tony Oruga

Network crews were working in an electrical room tasked to install an 800 A disconnect for a temporary service on the network secondary. The 3-spot network was energized at 480 V on the secondary (34.5 kV on the primary) and all three network protectors were closed and serving load. Each network protector installed was a 3000 A, 480 V Eaton CM52 unit equipped with an Arcflash Reduction Maintenance SystemE (ARMS). Prior to performing their work, crews enabled the ARMS function on all three units in the spot. This put all three network protectors in a “hair-trigger” mode, ready to clear any current condition that exceeded 2.5x the nameplate rating.

As part of standard utility work, all procedures were followed in accordance with their specific utility standard practices. The workers had the specified PPE for those specific work conditions. However, as in any work environment, unforeseen events still occur and crews are trained to deal with less than ideal circumstances. During this particular install, the worker lost positive control of the wrench he was using to install 500 kcmil cable to an energized copper bus. This resulted in the wrench hitting the unistrut, which created a path to ground between the unistrut and the live network secondary. The calculated available fault current at the collector bus is 101.2 kA assuming 25 kA symmetrical available fault current on the 34.5 kV primary bus with balanced contribution.

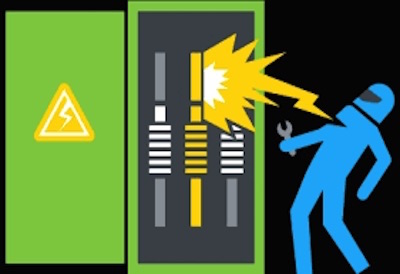

Because the ARMS protection system was enabled as a part of standard working procedure, each CM52 unit interrupted in approximately 1.9 cycles once the 7500 A threshold was met. According to crew reports, the ARMS device activated and cleared the fault before the worker noticed they had made contact with the energized bus. See Figure 1 for a depiction of the network arrangement.

[PLEASE INSERT EIN-34-WhitePaper-2.jpg HERE]

This technology has been proven with substantial test data to support its capability; however, this is the first report of the ARMS system being called to action during a network arc flash event involving real world circumstances that prevented severe injury or possible death to the worker. The purpose of this white paper is to share this event with others and help create a safer environment through technology for those working in these applications.

System characteristics

• Utility: Austin Energy

• Location: Austin, TX

• Network size: 3-spot network

• Transformer size: 2000 kVA delta-wye; 7% impedance

• Primary system voltage: 34.5 kV

• Secondary voltage: 480 V

• Network protector size: 3000 A; 480 V

• Network protector type: Eaton CM52

• Available incident energy: approximately 200 cal/cm2 (without ARMS considered) based on system analysis

• Available fault current on 480 V secondary: 101.2 kA (3 x 33.7 kA for parallel contribution)

• CM52 ARMS total clear: 1.9 cycles on average

• CM52 ARMS activation: at 2.5 x 3000 A (nameplate rating) = 7500 A

Go here for additional network protector ARMS technical information.

Tony Oruga is a product and sales manager for Eaton. This article was first published online: https://www.eaton.com/content/dam/eaton/products/utility-and-grid-solutions/network-protector-solutions/secondary-network-arc-flash-case-study-wp024002en.pdf