How LED Lighting Helps GoodLeaf Farms Increase Food Production

Dec 6, 2020

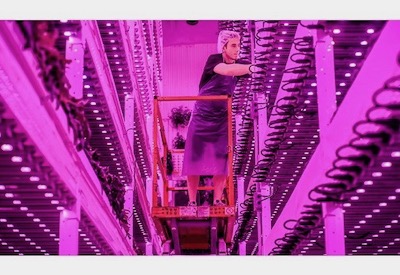

Image: an example of a warehouse farm with Philips Horticulture LED lighting.

If your salad greens come from GoodLeaf Community Farms, they probably grew under LEDs. GoodLeaf’s new state-of-the-art 4,000 m2 indoor vertical farm in Guelph, Ontario is fully automated and equipped with the latest LED lighting technology for growing indoors. GoodLeaf grows and packs fresh, nutritious, and pesticide-free micro and baby greens year-round, which the company supplies to some of Canada’s largest retail chains.

GoodLeaf equipped the farm with Philips Horticulture LED lighting from Signify to and increase food production, enhance flavour and improve nutritional value. The energy efficient Philips Greenpower LED production modules enable GoodLeaf to shorten production cycles. As it provides a controlled environment it also allows GoodLeaf to produce all year round without any lighting, temperature and pesticide worries, and reducing waste at the same time.

GoodLeaf Farms started working with Philips products in 2013 at the company’s test facility in Truro, Nova Scotia. Signify has built up a substantial track record in more than 400 projects in the horticultural lighting market since 1995, developing ways to apply lighting technology to crop farming. With cutting-edge LED innovations, the company can custom-build a science-based solution for growers providing data and plant expertise to optimize yields.

This expertise is built on close collaboration with Signify’s horticulture partners and through research at its own vertical farming research facilities in the Netherlands, called GrowWise Center. Vertical farming, or city farming, means that plants can be grown indoors in a controlled environment without sunlight. This is ideal for propagating young plants, cultivating full head crops and growing healthier, pesticide-free crops. It maximizes production by using LEDs to light multiple layers of crops, achieving a higher yield with a smaller footprint.

This large-scale production technique is ideal if you want to cultivate in a customized, closed environment of more than 2000 m2. Plant factories are very high-tech, highly automated, and can be serviced by robots. They also have fully automated irrigation, climate control and logistics with a growth process and production line that can be tailored to the crop. Sensors and data help to manage, steer and improve the process.

“The support from Signify and the folks from GrowWise Center is phenomenal,” says Jeff McKinnon, Chief Financial Officer and Vice President of GoodLeaf Community Farms and TruLeaf Sustainable Agriculture. “We meet with them monthly. The data they collect cover the data we collect as well, so sharing that knowledge has been excellent, and the service over their Philips’ products has been exceptional.”