Don’t Underestimate Your Estimating System’s Potential

Shawn McCadden

Knowing what to charge clients for the work you do is often the difference between long-term success and eventual failure for the business. Many contractors look at estimating simply as a way to determine the cost of a project. In the traditional design-bid model of project delivery, this simplistic approach may work, assuming your price generates enough gross profit to cover your overhead and profit requirements. However, if your current estimating system is limited to only producing the number you charge clients for a project, you may be missing out on many other possible benefits.

First, a few assumptions

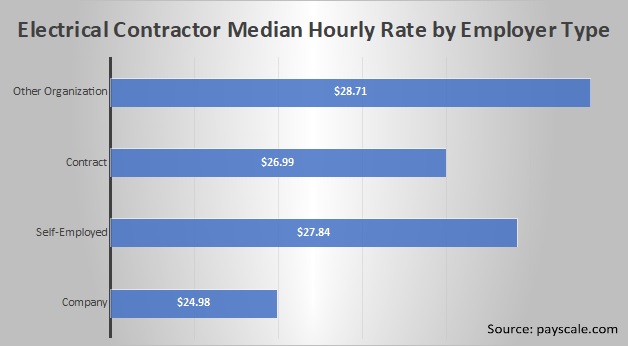

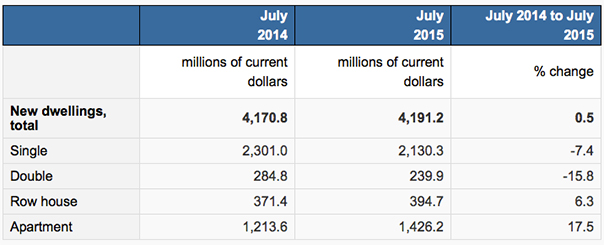

By gathering the material, labour, equipment and possible subcontractor costs of a project, contractors determine the direct cost of a project and then use a mark-up amount to determine the sell price for a project.For the sake of this discussion, we must also assume that the contractor has created a business budget. By knowing or predicting the costs of being in business for a predicted sales volume and adding in a net profit requirement, the contractor can determine burdened labour costs and know the company’s mark-up requirement over and above direct costs. We must also assume the estimator knows how to estimate and has experience estimating the kind of work the business performs. Your estimating system must become a tool that facilitates how you do business, not just a way to get to the price.

An estimating system should

• be fast and easy to use. Typically, the yellow pad and calculator method does not apply here. A computerized system allows the estimator to concentrate on estimating, not adding up numbers over and over again to gain or confirm confidence in the end result

• allow for on the spot “what-if” adjustments. The estimator must be able to quickly estimate the effects of any changes or suggested alternatives to the project during design.

By having this ability, the client’s decisions during design are better qualified by simultaneously knowing the financial impacts of those decisions

Estimating must be accurate and adequately detailed

To increase accuracy, estimating should be done so it is comparable to the company’s job costing system. Information within the estimate, and job costing, should be broken down to a level of detail that allows the insight you need to make future estimating adjustments.

Estimating in one computer program then job costing in another may become cumbersome, or may not work at all. Accounting programs will often allow job costing, but not estimating. Typically, after a project is sold, a summary of estimating information is entered into the accounting package as a budget for purposes of job cost comparison. This limitation does not allow for fast estimating or what-if adjustments. Also, it may not be easy, secure or wise to allow an estimator access to the company’s accounting information.

The formatting of each individual estimate, as well as the overall estimating system format, may be the most important consideration. How information is entered into the estimate can limit or expand how it can be used or who uses it. Strive for a format that allows the information created by the estimator to be shared throughout the company. If you build your estimate the same way you build the project, step by step, you can create a critical path for how the project will be produced. This can be a huge benefit to supervisors and others. A predefined path, showing labour and material breakdowns, allows your team to predict and schedule resources including subs, material lists, material lead times, just on time material deliveries, and overall labour requirements.

If done correctly, you can also use individual project information to create one master schedule for all company projects and resources. You will know when you need which employee or sub, depending on skills or abilities, and identify schedule conflicts or shortfalls before they occur. This critical path can also help identify cash flow needs during the project while assisting in generating payment schedules.

Separate costs and quantities

Another formatting consideration is how you break apart the information for each line item inside your estimate.Rather than enter lump sum amounts for materials and or labour, separate the costs and the quantities. By formatting your information in this way you can quickly apply what-if options for material substitutions, other material changes, and/or additional labour considerations for any changes. This also facilitates quick pricing updates when a client calls back two years later and wants to go ahead with the project.There’s no need to redo the entire estimate because you’re not sure how the lump sums were determined, just check for pricing changes as the quantity will likely still be the same.

Read more in EIN from Shawn McCadden:

3 Ways To Get Fewer Leads But Close More Remodeling Sales

Don’t Underestimate Your Estimating System’s Potential

Tips on Ball Park Pricing and Charging for Estimates

Is A Contractor Really a Salesperson If He or She Hits Send?

3 Ways To Get Fewer Leads But Close More Remodeling Sales

3 Simple Steps to Covering an Employee’s Non-Productive Time

Setting the Example: Getting Employees to Think Like Owners

Comparing Contractor Mark-ups Can Be Pointless and Very Risky

Don’t Put Your Business At Risk By Guessing At What Mark-up

Simple Profit Sharing Plan for Contractors

Check out Shawn’s website http://www.shawnmccadden.com/ and blog www.shawnmccadden.com/Subscribe-to-The-Design-Builders-Blog.

* “Understanding what impacts your construction company’s reputation,”

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 12](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)