How the IIoT is Delivering on the Promise of Asset Performance Management Part 1

September 28, 2017

By John Boville

If you had researched the Industrial Internet of Things online in the mid-1990s, there might have been a handful of results. But if you searched on terms like asset performance management, predictive maintenance, and computerized maintenance management, you would have found thousands of entries. While such maintenance automation is finally gaining a foothold in industry, realizing its full potential has been hampered by limited access to the contextual data related to things like system wear and performance degradation. As more industrial devices gain intelligence and Internet connectivity, however, their data histories are increasingly exposed, offering advanced maintenance applications a richer supply of data for analysis. And all indications are that the number of digitally-enabled industrial devices is growing dramatically.

CISCO[1] projects that more than 50 billion things will be connected to the internet by 2020, resulting in more traffic, more data, more storage, and more energy consumption. Looking at this from and industrial perspective, IHS reports that only 9.1% of the more than 23.8 billion process and discrete automation elements are currently networked, but the compound annual growth rate of such deployments will increase to 24.1% in 2019.[2]

As an example of how increasing digitization might improve plant operations, Schneider Electric senior vice president for strategy Greg Conary points to improved communications between drives and pumps: “Pumps are typically dumb assets. They turn based on the amount of electricity supplied to them. But if you can embed the pump operating curve into a drive, when it sends electricity down into the pump, it knows how fast the pump should be turning and if it doesn’t fit the profile it can contact someone to find out why,” he said. Increasing digitization of this sort will impact maintenance at all levels. As defined by ARC Advisory group, these include reactive, preventive, predictive, and prescriptive maintenance practices.[3]

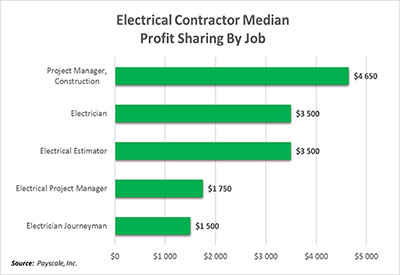

As ARC estimates, unscheduled downtime can approach zero when prescriptive strategies are applied. Predictive strategies can deliver twice the cost benefits of preventive strategies, and, in comparison to preventive strategies, reactive maintenance could increase lifecycle maintenance costs by a factor of 10 when a failure occurs. ARC sees IIoT offering new opportunities for asset performance improvement by combining the growing wealth of data with advance analytics.

|

Approach |

Method |

Application |

Cost/Benefit |

|

Reactive |

Run to failure, and then repair |

Failure is unlikely, easily fixed and/or non-critical |

10X plus when failure occurs |

|

Preventive |

Service in a fixed time or cycle interval |

Probability of failure increases with asset use |

2X maintenance costs |

|

Predictive |

Monitor a single process data value for bad trends and alert prior to failure |

Assets with random or unpredictable failure pattern |

1X maintenance costs |

|

Prescriptive |

Multiple variables with engineered algorithms and/or machine learning |

Longer range prediction of failure with high confidence |

Unscheduled downtime approaches zero |

John Boville is a marketing manager for Schneider Electric’s marketing and innovation group, where he focuses on the Modicon controller line. He has been with Schneider Electric industrial automation for more than 25 years, including implementing market segment strategies for the automotive industry. Prior to joining Modicon, before it became part of Schneider Electric, he served for 12 years in project engineering for CEGELEC Automation as an industrial system designer, installation specialist, and project leader for large automation migration projects. He holds a B.S. in electrical engineering from the University of Bradford, U.K. Keep up with John’s latest insight in his blog: http://blog.schneider-electric.com/author/jboville/

References

1.http://blogs.cisco.com/news/cisco-connections-counter

2. http://industrial.embedded-computing.com/articles/industrial-will-manufacturing-devices-networked/

3. https://www.linkedin.com/pulse/optimize-asset-performance-industrial-iot-analytics-ralph-rio

![Guide to the Canadian Electrical Code, Part 1[i] – A Road Map: 26 the Edition, Section 36 – High Voltage Installations](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)