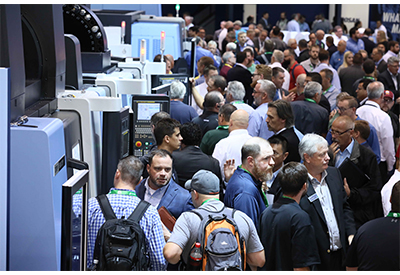

Focus on Digital Manufacturing at IMTS 2020

Feb 21, 2020

The International Manufacturing Technology Show is the premier destination to seek out existing and emerging manufacturing solutions. If a manufacturing solution can be digitized, automated or connected, visitors will learn how to implement it at IMTS 2020, which will showcase a full spectrum of digital and traditional manufacturing technologies. IMTS is organized into nine technology pavilions: Abrasive Machining/Sawing/Finishing, Additive Manufacturing, Controls & CAD-CAM, Fabricating & Lasers, Gear Generation, Machine Components/Cleaning/Environmental, Metal Removal, Quality Assurance and Tooling & Workholding Systems. IMTS 2020 runs from Sept. 14-19 at Chicago’s McCormick Place.

“The difference between IMTS 2020 and previous shows is that these core technologies now incorporate a digital component. IMTS 2020 represents the year the industry moved from conceptualization to implementation,” says Tim Shinbara, Vice President & CTO for AMT – The Association For Manufacturing Technology, which owns and produces IMTS. “By engaging with exhibitors, visitors can learn how to capture data and transform it into useful information that allows them to make better decisions. In short, digital manufacturing is good for your business.”

As an example, he points to “hybrid” machining centers that combine metal removal with an additive manufacturing or a joining process, a metrology process and automated part loading/unloading systems.

“These multi-tasking systems do more than just combine two or three processes to reduce set-up and handling time,” says Shinbara. “Hybrid technologies offer the ability to entirely re-imagine part design and production flow, radically reducing time to market.”

For almost every type of system, visitors can learn how to digitize operations in ways that measurably impact their business, such as using analytics to predict failure and have cloud applications automatically send maintenance alerts. Exhibitors will bring teams that combine skills to bridge the worlds of automation, manufacturing, IT, IIoT and data.

Visitors will also find a host of digital technologies related to machine interoperability, networking, data analysis, data security, ERP systems, machine controls and CAD/CAM software. They will notice that even basic “analog” products, such as a pneumatic valve, will now have an app available to adjust functions such as proportional pressure regulation, directional control, leak detection, timed motion, acceleration/deceleration and soft stops.

Go HERE for more information

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)