22 CE Code Changes Related to Wiring Devices and Cable Management, Part 1

July 21, 2016

Appearing below are the first 8 of 22 examples of Canadian Electrical Code changes involving wiring devices and cable management, compiled by Legrand. This is the first of a three-article series on the 22 changes. Watch for Parts 2 and 3 in the next two issues of Electrical Industry News Week.

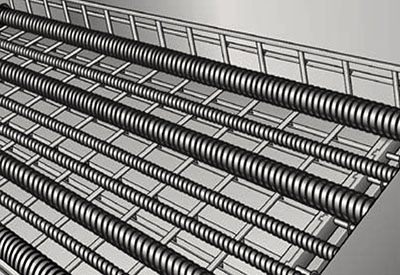

1. Rule 12-904, Subrule (2) —Conductors in Raceways

Conductors that are connected to different power or distribution transformers or other different sources of voltage are allowed to be contained within cable tray (shown in image).

The intent of Subrule (2) within Rule 12-904 is to prevent conductors connected to different power or distribution transformers or other different sources of voltage from becoming crossed and impressing another voltage on a circuit.

This is accomplished by prohibiting these different voltage source conductors from being installed in the same raceway or compartment channel of a multiple-channel raceway. However, a change to Subrule (2) now exempts conductors that are run in cable tray, provided that they meet the installation requirements summarized within the content of Rule 12-2202.

2. Rule 12-2200, Subrule (7) — Method of Installation: Cable Trays 2

Cable trays shall be permitted to have reduced clearances through chases, under gratings and process pipes, and around other such obstructions.

Although the proceeding Subrule (6) of Rule 12-2200 requires that adequate working clearances be provided to provide access to cable tray installations, modular assemblies such as natural gas compressor stations and gas plants may be required to have the electrical installation completed using a cable and cable tray as the wiring method. Due to the constraints of space in these units and within similar installations, it is often difficult to maintain these clearances as outlined. As a result, Subrule (7) now allows for reduced clearances in installations where the cable tray passes through chases, under grating, under process pipes and around other similar obstructions.

3. Rule 12-2208, Subrules (3) and (4) — Provisions for Bonding Cable Tray Systems 3

A new exception allowing metal cable tray to not be bonded to ground has been added.

While taking care to ensure that cable trays are installed as a complete system before any conductors or cables are run, metal cable tray is not required to be bonded to ground where all of the cables contained within the tray either have an interlocking metal armour, or have a continuous metal sheath that is permitted to be used as abonding method.

All metal cable trays that are not bonded due to this exception must be conspicuously marked with this warning notice: “INTERLOCKING METAL ARMOUR CABLES OR CONTINUOUS METAL SHEATH CABLES ONLY”.

4. Rule 12-3000, Subrule (10) and Rule 12-3002, Subrule (2) — Floor Boxes and Flush-Mounted Cover

New requirements for installations of floor boxes and flush-mount floor box covers.

Rule 12-3000, Subrule (10) was added to specify that floor boxes (similar to existing installation requirements of cabinets, outlets and terminal fittings) are also to be installed in accordance with the manufacturer’s installation instructions for the type of floor intended, as well as the requirement that these instructions are to be provided with the floor box product. Similarly, Rule 12-3002, Subrule (2) was added to establish a requirement that flush-mounted floor box covers are to be specifically approved for the type of floor, with accompanying instructions.

5. Rule 12-2208, Subrules (3) and (4) — Outlet Boxes, Cabinets and Fittings

Installation requirements addressing environmental ingress protection has been expanded to include wet locations.

New Subrule (3) requires that wet location cover plates are to be installed to ensure that the intended seal between the outlet box and the cover prevents exterior elements from entering the enclosure and causing corrosion. Correspondingly, new Subrule (4) requires that flush boxes, cabinets and fittings are to be of a type suitable for the intended locations, including those installation environments considered to be wet locations.

6. Rule 24-106, Subrule (7) — Receptacles in Basic Care Areas

Isolated ground receptacles are no longer permitted in basic care areas.

Subrule (7) was added to disallow the use of isolated ground type receptacles in basic care areas, as there was concern that redundant grounding required in these areas may not be adequately achieved when using isolated ground receptacles.

7. Rule 26-700, Subrule (13) — General Requirements: Receptacles

Receptacles considered to be inaccessible are not required to be tamper resistant. When receptacles of CSA configurations 5-15R and 5-20R are for dedicated stationary appliances or installed over 2 m from the floor or finished grade, they are deemed to be inaccessible to children. New Subrule (13) provides this exemption to Subrule (12) that pertains to child care facilities; receptacles that are located as described here within these locations are not required to be tamper resistant.

8. Rule 26-702, Subrules (2) and (3) — Receptacles Exposed to the Weather

New marking requirements and broader usage opportunities for these environments.

Subrule (2) now requires that receptacles exposed to the weather of CSA configurations 5-15R, 5-20R, 5-20RA, 6-15R, 6-20R and 6-20RA that are provided with cover plates suitable for wet locations whether or not a plug is inserted into the receptacle are to be marked “Extra Duty”, with the marking to be visible after installation. Subrule (3) now permits the covers for these same CSA configurations to be marked “Wet Location Only When Cover Closed” or equivalent when: (a) installed facing downward at an angle of at least 45° or less from the horizontal, or (b) installed at least 1 m above finished grade and not in a wet location.

Watch for coverage of the remaining 14 examples in the next two issues, respectively, of Electrical Industry News Week.