Motion Control Q&A with Electromate CEO Warren Osak

April 15, 2020

Founded by Warren Osak, Electromate specializes in Robotic and Mechatronic Solutions, distributing AC & DC Servo and Stepper Motors, Drives, Controls, Positioning Systems & Robots to the industrial automation market. They are also ISO9001:2015 Registered Company and LEAN Process accredited. You can find their full offering HERE.

Electromate was founded by Osak in 1986 and have become a leader in the industry on the strength of their technical engineering expertise combined with Osak’s extraordinary work ethic, approach to business management and philosophy of continuous improvement.

In the Q&A below, Warren discusses considerations for automating processes and provides some thoughts on the current motion and drives industry landscape.

What are some of the key things for a manufacturer to consider when introducing automation and control into a production process?

First, start with the end in mind. Define your requirement before you define your budget. Since the cost to increase the precision of a system jumps exponentially with every 10-fold increase in precision, it’s wise to first define your requirement in terms of the needs of the process. Far too often customers approach us asking for submicron bidirectional repeatability only to balk at the price. Then when we review the customer’s actual requirements, we often see that micron level repeatability is more than satisfactory.

Secondly, define what you hope to accomplish. Are you looking for localized control or distributed control? Localized control (at the machine level) is generally quicker to implement but has the limitation of no interoperability. By contrast, distributed control systems are more complex to set-up but offer connectivity to an entire production line which has many benefits such as managing Kanban or Demand Flow production processes.

Lastly, are you looking for a turnkey plug & play solution, or a custom solution specific to your needs? If the latter, it’s critical that you have onsite engineering support to maintain the operation of the machine.

How have advancements in Motion Controllers enhanced the capabilities of automation in manufacturing?

Over the last 10 years we’ve seen a convergence of Machine Control and Motion Control, whereby PLC’s are now performing more complicated motion control tasks, and Motion Controllers are now handling 500+ remote I/O points.

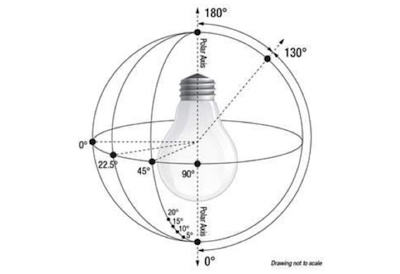

Additionally, the ability of Motion Controllers to perform algebraic functions have dramatically improved the capabilities of Motion Controllers, especially in the realm of Robotics. Forward kinematic equations have given way to advanced inverse kinematic equations where the positioning of a robot arm can now be calculated using trajectory planning for positioning the arm in any three-dimensional space.

What are some of the challenges of the current industry landscape, from your perspective as a distributor and solutions provider?

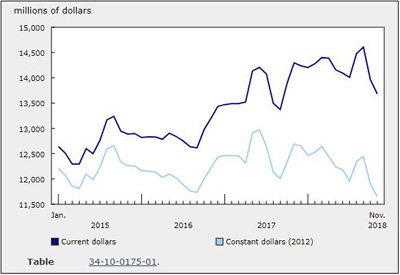

The Motion Control industry was born in the 1980’s, and as such is now considered a mature growth industry. While the industry continues to grow at a modest rate, it lacks the sex appeal of newer millennial industries, such as the IT/Cloud/Software Technology industry which is primarily controlled by the FAANG oligopoly comprising Facebook, Amazon, Apple, Netflix and Alphabet (formerly known as Google).

For many established companies in the Motion Control industry, competing for talent against these software behemoths has become a serious concern, especially as many of these companies have started or acquired their own Motion Control manufacturing divisions ie. Google’s Boston Dynamics robotics division.

What importance do you place on granularity with respect to products that are tailored specifically for a particular industry segment?

I wouldn’t say Electromate’s business is becoming more granular or segment oriented by choice. Rather, the nature of the products we offer tend to sell better in demanding applications, and thus our customers look to use to solve their engineering challenges.