Siemens and Toutenkamion Group Create Mobile Intensive Care Units for Hospitals

Oct 8, 2020

Siemens Smart Infrastructure has teamed up with Toutenkamion Group to jointly develop an agile container system of highly innovative mobile intensive care units, designed to take pressure off hospital infrastructure. The solution was a response to the Covid-19 pandemic, which forced nursing staff, doctors and hospital managers to urgently come up with practical solutions to ensure adequate care was provided to extremely contagious patients, while maintaining other emergency and conventional care. One of the major challenges of the epidemic has been the need to equip and increase the number of resuscitation and intensive care beds.

Toutenkamion, a French designer and manufacturer of customized mobile medical solutions for rigid lorries, semi-trailers and containers, created the skeleton of the mobile units. They selected suitable materials that are weatherproof and comply with regulatory constraints, particularly in relation to fire. The solution can be implemented quickly and moved from one location to another as needed.

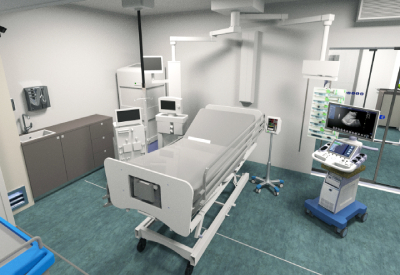

Siemens supplied the technology inside the modules so they can function safely and comfortably. This includes the electrical distribution, building management system, fire detection, safety, air treatment, production and distribution of medical gases as well as the integration of dialysis solutions through specialized partner companies – ATA Médical, Novair and Baxter. The design was also supported by the construction office Intérop.

Each intensive care unit is comprised of five single rooms: a nurses’ station, a pharmacy, a technical office, a biomedical equipment store and a dirty utility area for everything that needs to be cleaned. A staff rest room or office is optional. All the rooms are at least 23m2, which means that healthcare professionals can easily move around the patient to dispense critical care in the event of an emergency. Each room is also equipped with a patient lift for moving patients in intensive care.

One of the major benefits of the solution developed by Siemens and Toutenkamion is the speed and ease of implementation. It only takes eight months from planning to operations, including the manufacturing and assembly of the modules. French manufacturer Novair has supplied a complete system to produce and supply the medical gases used in the mobile units in total autonomy, using mobile generators. This autonomy preserves the hospital’s existing stock and network capacities. The mobile units are autonomous in the supply of normal and secured power.

The units can be adapted to purposes other than intensive care in pandemic times, for instance during ongoing works at a hospital. Equipped with ISO 8-class individual air treatment solutions, the units are particularly well suited to house dialysis or hematology units. They can also be supplemented by and connected to other medical and mobile functions already developed by Toutenkamion Group and Siemens such as radiology scanners, mammography, or ultrasound.