UL Laboratory in Italy Now Capable of Testing Plastic Materials for UVC-light Exposure

Oct 26, 2020

UL reaches another important step in terms of safety: UL’s laboratory in Carugate, Italy, has recently received a new accreditation that lets the laboratory team of experts test plastic materials in accordance to the standard IEC 60335-1 Annex T.

UL professionals can now conduct aging tests on selected plastic materials to verify any change of the material properties before and after exposure to UVC light. By doing so, their technicians verify that the exposure to UVC light has not modified the electrical or the mechanical characteristics of the material and it can be safely used if exposed to UVC light.

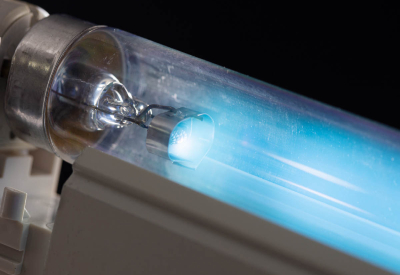

Due to the sanitizing properties of UVC radiation, more and more organizations are using UVC light in the fight against coronavirus. Several systems based on UVC technology were already used to disinfect surfaces and environments in hospitals and public places. Now that its disinfection power against COVID-19 has been found by several research studies, the number of products using UVC light has increased exponentially.

Robotic sterilizers, portable or stationary air filtering appliances, water treatment devices, handheld UV sterilizers are only a few examples of the products born in this moment, when disinfection is one of our most important needs.

If UVC light can help fight COVID-19, it also presents undue health risks if it is improperly contained. A person can suffer damage to the eyes, skin and even the lungs in a matter of seconds.

Similar to UVC’s harmful effect on people, UVC affects plastic, too. Products requiring the use of plastic may become brittle with a visible color change on the material’s surface. In technical terms, UV radiation causes photooxidative degradation, which leads to a break of the polymer chains and deterioration of its mechanical properties.

Additionally, plastic that has been damaged by UVC light can quickly lose its electrical and mechanical properties. For some plastics, UVC damage can lead to complete component failure altogether.

In consideration of the risks associated with the more popular uses of UVC light, UL’s team in Italy understood the important benefits of a new accreditation that would let them test the plastic materials used in conjunction with UVC-light. Davide Atzeni, UL operations manager, said: ‘”While there is evidence that UVC light may help fight COVID-19, it’s also important to consider the long-term safety of products continuously exposed to UVC rays. This new testing capability will help both manufacturers and end users be and feel safer.”

If you’re preparing to undertake a new project, it’s worth knowing which types of plastics are more susceptible to this type of degradation. Even better? Testing the plastic to make sure your new product will perform safely before manufacturing begins.