This New GE Factory Is a Blueprint for the Future of Manufacturing

September 01 2016

Welland has been known for decades at the city where rails meet the water. But the Canadian transportation hub, long known for a canal that linked Lake Ontario and Lake Erie with a cluster of railways, may soon redefine how things are made in North America. That’s because GE broke ground last month on a brand new “brilliant” factory in the city, located just across the Canadian border from Buffalo.

The brilliant factory is GE’s new take on how we make things. It involves machines embedded with sensors and connected to the Industrial Internet. The factory uses GE’s Predix software platform to stream data (over secure Industrial Internet links) into the cloud for analysis. Insights are then sent back to engineers with suggestions to improve operations. The divide between the lab and the factory also disappears in this approach, allowing for faster prototyping and commercialization of parts, according to Stephan Biller, chief manufacturing scientist at GE Global Research.

Biller is one of the big brains behind the concept. He’s developing ways to use data and analytics to transform factories into places that constantly improve their operations and output. As a result, Biller says, factories no longer need to be located where labour is cheap but can bloom where educated workers can make the most out of advanced technology. “By utilizing automation and the brilliant factory concepts, we are strengthening the base of North American manufacturing and equalizing the region’s ability to compete with countries where labour costs are cheaper,” Biller says.

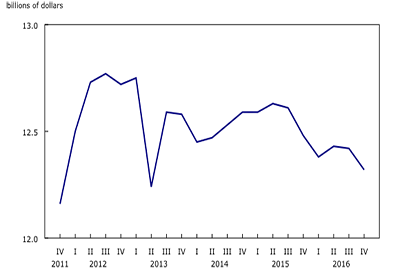

Welland makes a big point in his case. The city is located in Ontario, where the manufacturing sector has been hit hard in recent years. It lost some 300,000 jobs between 2000 and 2014, according to a 2014 report by the Mowat Centre at the University of Toronto’s School of Public Policy and Governance. The report says that Canada can bring back jobs by supporting research, educating workers and committing to boost productivity.

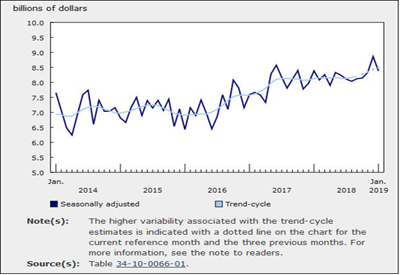

GE says the new factory, which will make massive gas engines and other components for GE businesses, will employ 220 highly skilled workers. Data and analytics will give them insights to improve quality output and increase profits, Biller says. The new approach will also shorten supply chains and reduce inventories.

GE plans to complete the Welland plant in 20 months. Elyse Allan, president and chief executive of GE Canada, said support from Canada’s export credit agency, Export Development Canada was key to the decision to build in Welland.

GE’s US$165 million investment in Welland follows its recent plans to build similar factories in the U.S. In Greenville, South Carolina, GE Power opened Advanced Manufacturing Works last spring. In April, GE also opened the Center for Additive Technology Advancement in Pittsburgh, to help take “additive” manufacturing methods, such as 3D printing, reach mainstream.