Enterprise IoT: What Is It, and How It Will Improve Energy Management (Part 1)

Jan 22, 2016

Those charged with a facility’s energy management are beginning to hear the phrase “Internet of Things” (IoT) increasingly often within the industry, and many are asking how to use the concept of the “Enterprise IoT” to leverage the data in their buildings and find opportunities for improvement.

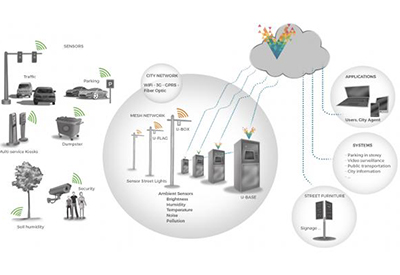

Photo source: www.smartindustry.com

In simple terms, Enterprise IoT can be defined as the many sensors that produce data within a smart building’s infrastructure. Physical objects such as wireless sensors within lighting, HVAC or security systems have embedded computing capabilities that, when connected to a central system, can result in operational efficiencies and reductions in energy. Most large commercial buildings — warehouses, office buildings, sports complexes, retail space, convention centres, etc. — encompass a variety of systems that require energy and can be connected via a wireless network.

Enterprise IoT comprises wireless networks, devices and sensors that are controlled by intelligent software. This combination of technology allows companies to collect data, analyze what is happening across a building or portfolio of buildings and make ongoing improvements that have a tremendous impact on cost cutting, while at the same time increasing operational efficiency.

Easiest place to start: lighting, HVAC, plug load

“Enterprises looking at building automation tend to begin with a focus on controlled lighting, as that is the most prevalent network in the building,” says MandeepKhera, VP of marketing and channels for Daintree Networks, a provider of smart building control and operation solutions. “If the solution you choose provides actionable data, you may discover that you have your lights going full blast when nobody is in the area, or that you are not dimming the lights during the day and making use of daylight harvesting. That wastes a ton of energy. Or you might learn that the lights are too low in certain areas, causing difficulties for workers.”

The beauty of Enterprise IoT is that devices such as light fixtures are no longer simply light fixtures. “We do not see light as a binary function device anymore, but as a node for data communication that can help facility managers and building owners learn more about their energy usage,” says Ben Pouladian, President of Deco Lighting, a provider of lighting fixtures and systems.

The next area on which companies tend to focus is HVAC. With a wireless control system monitoring activity, energy managers may find that they are blasting the AC in specific areas, or even in the whole building, when it is not occupied. Next generally comes a system for analyzing plug loads, allowing the company to look at all the machines in a facility, including printers, copiers, or heavier machinery that are plugged into outlets. Many of these stay on all day, every day, even when nobody is using the machine.

“This is the low-hanging fruit, the area where most enterprises begin,” says Khera. “From a pure energy savings point of view, these are the biggest three. However, none of these exist in a vacuum. They may be the obvious places to start, but remember to consider how the systems will build upon each other and work together in the future.”

Developing a long-term energy plan requires integration

While lighting, HVAC and plug load may be the obvious first steps, think before you start, warns Noah Goldstein, Research Director with Navigant. “You want your retrofit to fit into a general energy management strategy. Don’t just think, ‘Lights first, then we’ll finish and move onto HVAC.’ Think about your 10-year energy plan and then make decisions about your retrofits that fit into that plan.”

Goldstein believes companies aren’t thinking often enough about how to integrate systems for long-term benefits. The challenge of such long-term thinking is that the conversation about systems integration also involves the integration of decision-making and the integration of action, he says. ”Most facility or energy managers have largely been working on a single system at a time and not necessarily working with any other part of the organization. Generally, IT and operations exist separately. When facility managers install new lighting systems, for example, they may not even be working with the IT team. They may not realize that, moving forward, there is not sufficient infrastructure to support a continual addition of new wireless systems. And both IT and operations must integrate with the C-suite. The challenge of IoT is that it necessitates greater decision-making.”

5 things to consider when creating an energy plan

When considering a long-term energy strategy that involves system integrations, take into account the following elements:

1. Compliance

As environmental concerns intensify, building owners and corporations must carefully scrutinize their energy management and monitoring solution to ensure it fully complies with all mandates and regulations. These include automated demand response, plug load circuit control, daylighting, and multi-level lighting controls.

California, for example, has set out energy efficiency standards in the state’s Code of Regulations Title 24. The California Energy Commission recently updated Title 24 Energy Efficiency standards, requiring businesses to implement technologies that enable highly efficient and zero-net-energy buildings with systems that are integrated with advanced communications capabilities. The standards ensure that better windows, insulation, lighting, ventilation systems, and other features that reduce energy consumption are installed in businesses. The new standards lower the threshold for when alterations must comply with standards and allow fewer exceptions. For example, now Title 24 requires lighting alterations to comply with the most recent standards when 10% of the luminaires are replaced, down from 50% in the previous Title 24 version.

Taking advantage of Enterprise IoT by installing wireless control systems helps ensure that building owners and companies meet these standards.

And it makes sense to implement these solutions now when a building is being built or upgraded to save money in the long term.

Six months before the new Title 24 was to be enforced in California, Universal Music Group was planning to move its headquarters to a different building. Because the company was moving just before the new standards were enforced, they originally considered ducking under the new standards, thinking they would save money on new installations. “After discussing it at a corporate level, we thought, ‘We’ll be here for at least 10 years. We want to invest the money now; it’s better for employees and for us in the long-range,’” says Kevin Garabedian, Universal Music Group’s VP of Administrative Services and Facility Operations.

As standards look to become ever more stringent in coming years, energy efficiency needs to be viewed as a facilities management and IT investment that helps optimize building operations. Companies may do well to avoid disparate systems that cannot interoperate and therefore cannot be leveraged for adjacent energy cost saving opportunities.

2. Wireless

Wireless control solutions have the capability to transform a building into a connected, intelligent facility that responds automatically to various needs. The end result is unprecedented visibility, automated fault detection, and centralized monitoring and control that empower the facility manager. Making use of Enterprise IoT requires wireless systems, as the sheer number of wired devices would make their integration impossible.

Using wireless systems, Bluestone Energy designed and installed a comprehensive solution for Computershare’s Canton facility, a three storey, 215,000 square foot office building. In addition to a retrofit of the lighting for their garage, Bluestone implemented setback and scheduling of the RTUs and fan powered boxes (FPBs) via a new Building Automation System. This system significantly reduced cooling, heating and fan energy, and eliminated short-circuiting that was occurring from supply to return.

The project had a simple payback of less than half a year, and resulted in an annual energy savings of 2,500,000 kWh.

In another decade, buildings without advanced wireless controls will be as rare as analogcellphones from the nineties, believes Sachin Andhare of Daintree Networks. “As for the wireless controls payback, the typical range is between one to four years based on the application. The declining hardware prices will reduce the payback period even further and take wireless network control solutions to the next level,” he says.

“And installing a wireless system is easier and less problematic than putting in a wired system,” says Garabedian. “There’s no, ‘We forgot to run a wire,’ or, ‘We forgot to put in a conduit.’”

When the Universal Music Group installed wireless systems in its new headquarters building, Garabedian found that, while the hardware for its wireless system was more expensive than those for a wired system, the labour was less. The total installation cost no more than installing a wired system, he says.

A wired control system for something like lighting can be efficient in and of itself, but wireless controls that allow all building systems to work together can bring as much as 70% energy savings across the board, according to Daintree.

In Part 2: 3 more elements to take into account when considering a long-term energy strategy that involves system integrations.

This report was first published by Daintree Networks. Download the entire report here: www.daintree.net/resources/enterprise-internet-of-things-what-is-it-and-how-will-it-improve-energy-management/.

![Guide to the Canadian Electrical Code, Part 1[i] – A Road Map: Section 52 — Diagnostic imaging installations](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1[i] – A Road Map: Section 52 — Diagnostic imaging installations](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)