Building a New Power Line Gave BC crews a Chance to Shine

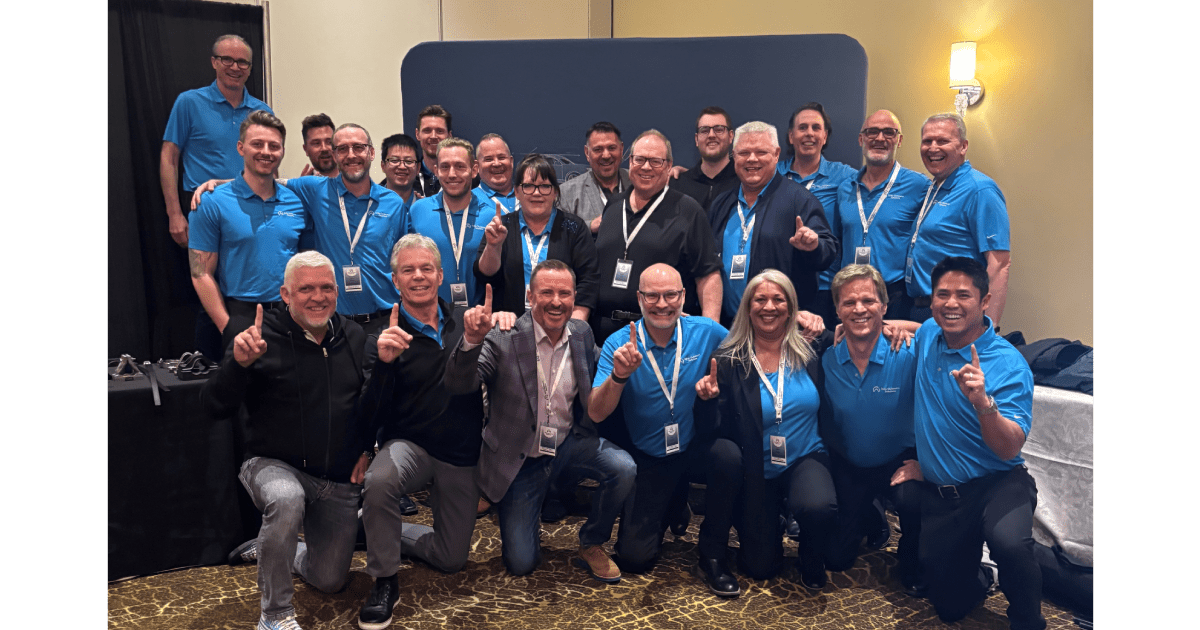

Stringing new power lines, called conductors, requires careful coordination between crews on the ground and helicopter pilots.

Foreman Bill Dalling can’t imagine doing anything else but working in the line trade. His crews worked on slopes of up to 30% grade capable of snapping chains or towing straps securing heavy loads. And then there was the spring thaw, where snow turned to mud “thick like gumbo.”But to hear Dalling describe it, building a new transmission line is about as good as it gets, at least for someone who’s made a career out of building power lines.

Dalling has been working since August 2014 as the foreman for the Merritt Area Transmission Project, leading BC Hydro construction crews as they built the 35-kilometre, 138-kilovolt transmission line, scheduled to be in-service in the fall of 2015.

The new line, which passes through tough mountainous terrain in B.C.’s southern interior, begins near the Highland substation 12 kilometres south of Logan Lake, and continues up over the mountains towards the Coquihalla Highway. It will provide power to the growing community of Merritt and the surrounding area.

The construction services team was responsible for every aspect of constructing the transmission poles and stringing the conductor, and as he explains, it’s not exactly easy.

Crews start by clearing a right-of-way for the new line

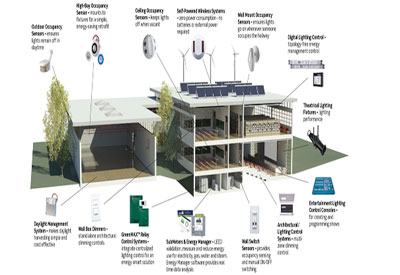

Before the familiar power poles can be constructed, and before power lines can be strung into place, crews need to clear the next stretch of right-of-way for the transmission line. Access roads need to be built so that trucks and equipment can access the transmission line route, and vegetation needs to be cleared to ensure crews can work safely.

Once the right-of-way is cleared, setting crews can move in to place the structures. In this case, wooden transmission towers known as “H-frames.” Part of his role was to coordinate construction so that the 30-person crew could always easily and safely move on to work on erecting the next structure. Once the structures are up, the chopper moves in. Thanks to the steep terrain and the difficult access along the transmission line route, the power lines are strung by helicopters, working closely with crews on the ground.

Helicopter pulls lines into place – carefully

“It starts with stringing what’s called hard line steel,” says Dalling, explaining that the hard line steel goes through pulleys called travellers in a series of structures, six kilometres at a time. These act as the ‘bull line” that attaches to the actual power lines, known as conductors, and is pulled by the helicopter to string the conductors through the same travellers. One of the important parts of stringing the lines is ensuring the appropriate “sag” in the line. There aren’t a lot of times in life when something sagging is positive, but building a power line is one of them.

“Every power line in the system has to be sagged according to the outdoor temperature to allow for expanding and contracting,” says Dalling, adding that it’s critical to get just the right amount of slack in the lines. Seasonal fluctuations in temperature, especially in colder climates, can wreak havoc on transmission lines and poles.

“In the winter, the lines can contract so much that they can break structures and poles as they pull tighter if they’re sagged improperly,” he says.

And if contending with helicopters wasn’t enough of a challenge, building a power line in B.C. is never easy. Crews here face some of the toughest terrain around.

“We were working in deep mud, it was like gumbo”

The terrain was steep and rough, says Dalling, and something as simple as keeping your footing while you were working was a challenge. Working through the winter meant slippery, snowy conditions, and the warmer weather wasn’t any easier, creating deep mud everywhere that the crews needed to work.

“We were working in deep mud some of the time, it was thick like gumbo,” says Dalling of the conditions setting crews faced as snows thawed.

And the mountainous location made it harder to keep track of the crews. Like most construction sites, safety is paramount, particularly with helicopters working overhead. Crews need to stay in constant contact, but there’s limited radio communications in the mountains around Merritt.

Crews would be stationed as much as six kilometres apart, so often someone needed to be placed in the middle to relay messages from the yard to the site where the stringing was taking place.

And at one end of the new line, near Highland Substation, crews were working parallel to an existing 138-kilovolt line, creating additional hazards and challenges in order to create proper grounding and work safely near a live power line.

Despite the challenges, Dalling is upbeat and enthusiastic about the whole project, citing it as a great one for the team, which included working with additional BC Hydro construction crews from Prince George and Nanaimo. As he says, everyone really enjoyed the project, did an exceptional job, and there was a great sense of camaraderie around the crew from beginning to end.

And for Dalling, that’s what he’s looking for each time he heads to work in the morning. Construction services gives him the opportunity to work on the whole spectrum of the power line trade, from building transmission lines, working in substations to working on distribution lines.

“I really enjoy this trade, I can’t think of doing anything else,” he says.