8 Tips for Choosing a Step-down Transformer

June 3, 2020

By Max Ezzati

Step-down transformers allow any electrical product to be installed on 347V circuits, which is why many electrical contractors keep a few in their car stock. Selecting the correct step-down transformer ensures the physical dimensions of the transformer are as small as possible to fit easily in the junction box while keeping costs as low as possible. Here are our tips on selecting the best step-down transformer for your job.

1. Check the line voltage

You may believe your line voltage is 347V, but we measure it; it is difficult to be certain. Some line voltages are rated 347V but experience voltage fluctuations bringing it as high as 400V+. These voltage fluctuations may prematurely wear the step-down transformer and shorten its life cycle.

2. Check the input voltage on the electrical product

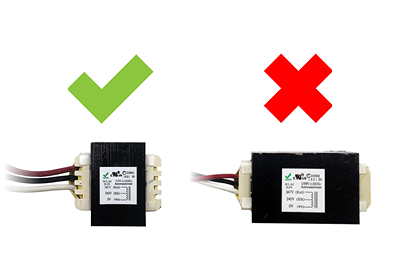

While some electrical products accept only an input voltage of 120V, many take universal inputs of 120-277V. In the latter cases, selecting a step-down transformer that only brings the voltage down to 240V instead of 120V will mean a smaller transformer that costs less.

3. Minimize the transformer power where possible

If your electrical product uses 40W, using a 50W step-down transformer is always better than using a 100W version. Once again, this makes installation easier since the transformer is smaller, and will cost less for the same result.

In applications involving long extended wires, or if the product is installed in an area of high heat, always take into account the expected voltage-drop, wire resistance, and power loss in the wires and the product itself.

4. Verify the efficacy of your step-down transformer

For example, Arani’s step-down transformers have an efficacy of 89%, meaning on a 50W transformer you should not install a product of higher than ~44W. Always give a bit of safety allowance by not maxing out the effective power to ensure the transformer does not fail.

A step-down driver that is pushed to its limits may work momentarily, but will fail over time as the transformer warms up. This increased temperature increases resistance in the coils of wire, generating heat, which in turn further increases the resistance in the wires — a vicious cycle that results in a rapid drop-off in transformer efficiency and eventually failure.

5. Check the physical dimensions of the box/housing as compared to the step-down transformer

If your application does not have much room to house the transformer, the dimensions of the transformer are crucial to stay compliant to code. Refer to tips 1 and 2 to minimize the physical size of the transformer.

6. Keep the step-down transformers physically protected

Step-down transformers consist primarily of coils of wire and magnets, and as such have an extremely low rate of failure. However, they are still susceptible to physical damage if left in unprotected environments. Keep your step-down transformers away from the elements, and pay attention to any strong electromagnetic fields that could damage the arrangement of magnets and wires in the transformer.

7. When installing a lighting fixture, verify the dimming requirements of your application

For 0-10V dimming, a step-down transformer will not affect the dimmability of a lighting fixture. However, for regular dimming such as triac dimming, the fixture will no longer be dimmable after installing a step-down transformer.

8. Calculate your total costs before assuming step-down transformers are right for your application

While step-down transformers are convenient and effective, in certain cases it may be cheaper to simply change the circuit voltage at the panel from 347V to 120V. If your system does not involve much wiring in the first place, or if you are adapting an existing high-load system to a smaller load system, you may wish to consider changing the panel from 347V to 120V.

To view Arani’s line of step-down transformers, click here.

To contact Arani, click here.

Max Ezzati is Project Manager at Arani

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)