Cabling Certification: Multi-Everything Is the New Normal — Part 1

Feb 19, 2016

Today’s IT discussions are filled with such terms as Cloud, Virtualization, SANs, BYOD, SaaS, and SLAs. Rarely is the physical layer — Layer 1 of the 7-Layer OSI Model — part of the buzz. But at the end of the day, all network technologies lead back to that critical, foundational layer and the cabling infrastructure that supports it. If it doesn’t work, nothing works. And like the technologies around it, it is changing. Consultants and network owners that do not embrace this change, and address the mounting complexities of installation and certifica¬tion, will struggle for profitability and the very survival as a business.

This white paper explores the state of the cabling industry — where it has been and where it is going. It evaluates what it takes to succeed in the face of an exponentially greater need for cabling contractors to manage multiple environments, media, standards, and technologies. In this new multi, multi, multi world — the new normal — what do cabling professionals need to do differently to ensure success and profitability? What is needed to properly navigate the changing landscape of media, standards and more? And how can we, as a professional community, change the project management game?

The evolution of datacom cabling

Data centres and the networks that fan off from them settled into a fairly archetypal design right around the year 2000, and haven’t altered dramatically since then. The data centres themselves were composed of racks of servers and tiers of switches. And, the copper connections ran to desktops, routers connected to the Internet, and appliances were inserted for security, storage and other applications. The No. 1 challenge for cabling contractors: speed of certification.

But, big changes are afoot. Standalone servers and storage have been virtualized, and that virtualization is driving increased density, and subsequent demand for ever-better performance, in the data centre. The classic data centre network, built on a three-tier architecture of access, aggregation and core switches, is collapsing into a single-hop network fabric that promises to help deliver dramatically better performance. Organizations are starting to displace proprietary switches with Software Defined Networks built on commodity hardware and open source traffic management software.

In the horizontal leg of the network, the Ethernet connection is being overlaid by an increasing number of Wi-Fi connected devices. The era of BYOD (Bring Your Own Device) is significantly affecting on networks — surveys indicate that more than 80% of organizations now allow users to bring personal devices onto the wireless LAN. And with its issues of propagation, interference, rogue access, constant evolution, etc., Wi-Fi adds strain and complexity to the underlying infrastructure.

A key reason for the stasis in the networking industry over the past decade had been the effectiveness of 1 Gbps copper connections. These cables were common, inexpensive, fast enough, and relatively straightforward to install and repeatedly test. But, that era is coming to a close as we move from 1 Gbps copper to 10 Gbps copper, and to 40 Gbps and even 100 Gbps fibre. As more data travels over each connection, each cable is that much more critical.

Evolving challenges

Complicating matters further is the issue of evolving standards. Where Cat 5 cable used to rule the day, now there’s Cat 5e, Cat 6, Cat 6a or Cat 7 copper, and multiple types of fibre. There’s a broad range of industry standards, measurements and compliance requirements — TIA vs. ISO, EF, TCL, CDNEXT, TCLT, ELTCTL, etc. And for Wi-Fi, there’s 802.11a, b, g, n and soon ac (gigabit) and eventually ad (7 gigabit). The traditional notion of “pull this Cat 6 and connect it to the server rack, pull this Cat 6 and connect it to the switch, pull this Cat 5e for the LAN” is going away.

Simultaneously, the people who are responsible for deploying and maintaining this infrastructure — the cable installers, project managers, network administrators, etc. — are wrestling with limited resources. Time and money are certainly the most obvious constraints: the need to get more done, faster and for less.

Less-recognized issues are the twin constraints of manpower and expertise. There are fewer trained personnel available to do the work (specifically in terms of ratio between installer/installation), and those that are available may have limited expertise. As with many industries, there’s a growing divide between the project managers, who have professional certifications and substantial expertise across a broad range of installation and testing requirements, and the techs or installers, who have more limited training, isolated expertise, and may even be temporary workers.

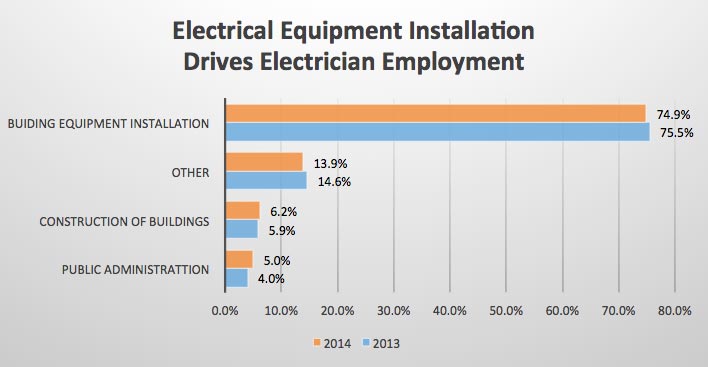

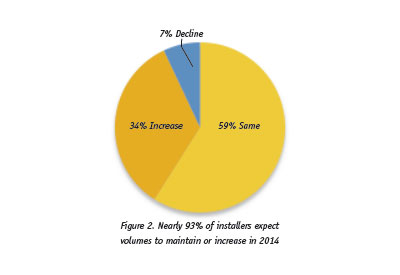

Not only is complexity increasing, but the volume of cable installation and certification is still high. According to surveys, nearly 93% of contractors expect to certify the same (59%) or a higher volume (34%) of links next year (see Figure 1).

Testing and certification are key requirements for these installations, and not just for the obvious need to make sure that everything works. Certification reports are generally required for payment, to comply with manufacturers warranties, and to facilitate troubleshooting.

Yet because of the volume of work and the scarcity of resources, roaming install/test teams and separate service tiers are common. Almost 90% of these links are typically fixed individually and immediately, meaning that if a tool or expertise is not available, work stalls until it gets there. And the test equipment travels with these teams: 55% of installers in a recent survey moved their tools several times a month, not just from one site to another, but back again.

Adding to the complexity, installations are not problem free: In recent Fluke Networks customer surveys, 91% of U.S., 90% of Asian and 97% of European installers report at least one problem. More than half of the respondents from the U.S. and Europe report seven or more problems. In Asia, that climbs to 10 or more problems (see Figure 2). While those problems are frequently issues with the cable or installation itself, they are as likely, if not more so, to be errors in process: incorrect test limits; misconfigurations or parameters; test data spread across multiple testers; mismatched results, incomplete testing or reporting, etc.

And those problems add up, according to the research. In total, in any given month, more than 22,000 hours in the U.S., 18,000 hours in Asia and 4,000 in Europe are spent resolving cable infrastructure issues. That works out to 45 hours (U.S.), 61 hours (Asia) and 26 hours (Europe) per 1,000 cable links on average, depending on region. In simple terms, the mistakes, complexity and rework can add a week to a week and a half of labour to a typical 1,000-link project. This is a worldwide problem, with global scope but unique geographic impact.

Right now, the industry is awash in “multiples” — multiple cables, multiple standards, multiple teams, multiple tools, multiple projects, multiple test regimes, multiple skill levels and more. That puts two opposing forces — increasing complexity and thinly stretched expertise — on a collision course that affects the fundamental connectivity of technology.

Critical point

The implication is that if something doesn’t change, then some other factor has to give. If complexity continues to increase, and resources don’t increase commensurately, then there will be a steady increase in either time or cost per install. It will either take longer to test and certify links, slowing growth until volume, complexity and resources reach an unsteady equilibrium; or the cost will begin to rise, allowing additional expertise and resources to catch up to growth in volume and complexity.

Imagined potential

Clearly what’s needed is better efficiency and agility, and that means tools that can assume a larger role in the installation process, thereby delivering a greater impact on the business. Yet over the last decade, the nature of that efficiency and impact has evolved.

When Fluke Networks originated the modern cable certifier, the DTX CableAnalyzer Series, in 2004, it met the demand for speed in testing each link. The DTX revolutionized the industry, delivering accurate and reli¬able results many times faster than anything else on the market. As a result it is the leading solution in the industry, and has been for nearly a decade.

But as the industry has evolved, so too must the tools. As much as testing and troubleshooting are the core of certification, there is an even greater opportunity to wring time, cost, complexity and errors out of the rest of the process.

In Part 2: the 6 steps of a certification process and the future of certification.

This white paper was recently published by Fluke Networks, the world-leading provider of network test and monitoring solutions to speed the deployment and improve the perfor¬mance of networks and applications. Leading enterprises and service providers trust Fluke Networks’ products and expertise to help solve today’s toughest issues and emerging challenges in WLAN security, mobility, unified communications and data centres. Based in Everett, Washington, the company distributes products in more than 50 countries. For more information, visit www.FlukeNetworks.comor call +1 (425) 446-4519.

*All research in this white paper is based on a Fluke Networks research study.