David Johns: A Teaching Perspective

January 8, 2018

By EIN’s Editorial Team

David Johns is a unique and dedicated individual both at home and in the workplace. At home he is a dedicated husband and father, but when the work days starts David spends most of his time teaching a new wave of electricians. David is an electrical apprenticeship instructor at the Southern Alberta Institute of Technology, where he provides industry training to students in all levels of their training.

EIN had an opportunity to ask David several questions about his career as an industry professional and veteran instructor.

Tell us a little about yourself.

I am from Calgary, Alberta and have been here for the last 30 odd years. There are three kids ranging from 5 to 10yrs at home with my incredible wife who looks after them. We have an abnormally large wolf type dog who has become a large part of our family. We enjoy taking him for walks at the dog park as a family. Hobbies are typically centred around family activities, church and our summer vacations.

Why did you choose to pursue a career in the electrical industry?

The electrical field was the one in which I had the most interest in when I was determining which career path to take. I had always had a keen interest in electrical related topics, it is one of the major areas of life that is invisible-but incredibly complex.

Tell us a little about your education and work history and how you arrived at your current position.

My work history was varied prior to coming into an instructor position. I had received my journeyman Red Seal certificate after working in many positions within the residential and industrial sectors.

The industrial sector was my primary area of interest; there was so much attention to detail that was required with different pieces of equipment that all worked together — generators/NGRs/PLCs/MCCs/different pipeline monitoring equipment.

I spent a lot of time building oilfield skids for a small company. They were small enough that one individual was able to build all the electrical inside. The experience was invaluable. Planning pipe runs, reading prints, moving equipment, interconnecting-all done by one person.

After being given the opportunity to teach in Calgary at the Southern Alberta Institute of technology (SAIT), I transitioned to a classroom setting. I have been teaching for the last 10 years, and taking various other courses and training as time has permitted.

I managed to keep my hands in the electrical field over the years, but inevitably it becomes a challenge due to the restriction of having only 24 hours in a day. Over the years I have taken time to update my education, as time has permitted. I currently hold a master electrician certification, Safety Codes officer certification, and BC provincial instructor diploma. Most of these are specific to Alberta, but each province has some sort of equivalency.

As an electrical instructor today, do you see many differences in the way you were taught how to teach? And do you find that your experiences from when you were learning the field have impacted how you teach your students?

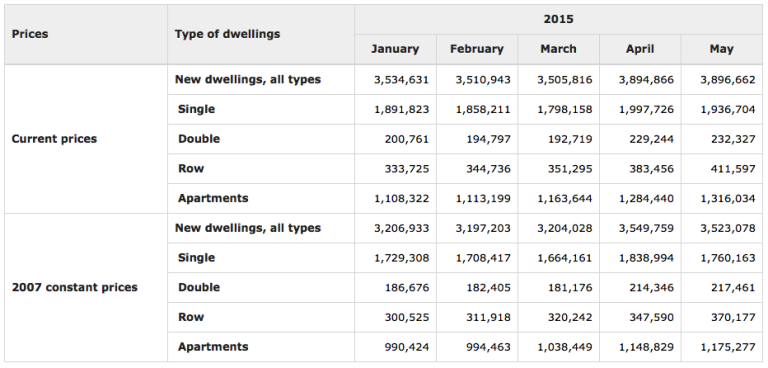

Yes, I see a lot of difference from when I was first in school. The majority of my focus — and difference of approach — has stemmed from learning about the Canadian Electrical Code, Part I.

For years I had been taught that it was simply a series of rules with little to no justification for the rationale. Few to no items were ever brought into the classroom to lend validity to the topic. Within the realm of classroom training, the CEC can very quickly become a game of linguistics rather than an education of electrical concepts and requirements. I think most instructors struggle with this from time to time. With the availability of the Internet, and scrounging through discarded equipment, I have been able to bring accurate images to students that help them to see and hold the actual item that is being discussed. It is challenging for students to apply rules of the CEC if they cannot see what the rule is discussing.

The topic becomes much easier to learn and discuss with a class when there are historical reasons, technological changes, dangerous situations that have led us to a present CEC rule or change to a rule. Avoiding straight lecture in the classroom is a constant challenge, as some topics warrant such an approach. At times this can’t be avoided when sizing conductors and service requirements, but for the majority of topics visuals or equipment brought in helps to connect the CEC to reality.

What is the biggest challenge in being an electrical instructor today?

Not being able to work on the tools in larger electrical projects. At times it can be challenging to learn how things should be done and teach how it should be done, but not be able to put those skills into practice in real electrical projects.

How do you stay ahead of the changing technology and industry trends? And how do you relate the importance of this to your students?

I ensure to keep tabs on what industry is discussing. Conferences are always of interest when it comes to new trends. At the end of the day, the electrical field is simply too large for any individual to fully track all advancements on a yearly basis. I ensure my students are aware of the broad spectrum our trade permeates through. This typically means there is something of interest for everyone. Electrical has so many applications; it is unique when compared to any other trade. Plus, everything that is gaining momentum in our world typically involves the need for more electricity. Climate change is typically combatted by reducing the consumption of fossil fuels. Usually electricity substitution is the first step: renewable driven wind solar and tidal generation. Improving living conditions in developing countries-electrical. Vehicle electrification. Not carpentry, not plumbing, not welding. Electrical. Our sector is growing exponentially, and I don’t see that changing anytime soon.

How vital do you feel it is for students to get a combination of practical and in-class training?

It is incredibly important. It is also incredibly challenging. Practical experience requires a large amount of square footage, funding for consumable materials, funding to update for modern equipment, skill-appropriate projects, and time. In Alberta, our training material and time schedule are determined by the provincial government. Sadly, actual hands-on training has become a back-burner topic that is seen only in pre-employment type programs. This is fairly common across most provinces, although exceptions exist. Interesting enough, electrical could be considered a “scholastic” trade as it focuses on the “why”: electrical physics, electrical code, electrical equipment. If contrasted to any other trade, this is a unique situation.

Carpentry, plumbing, welding, instrumentation, automotive mechanics all learn about the “why”, but they also learn the “how”. An automotive mechanic learns about why an engine functions, and why different procedures are required for an engine rebuild. The difference is that they actually do an engine rebuild at some point during the apprenticeship training. They are shown “how.” Students in other trades build or construct something that would be expected of them in the field, and are then evaluated on it. They have to know how to do the task, and execute the process neatly and accurately.

By comparison, electrical students have a much different experience. Our students connect equipment in labs with connections that mimic reality. Labs are connected with removable wire leads (no tools) to modified equipment. This at times can make some topics harder to understand. In addition, the actual installation requires a substantial number of skills that extend much further than simply an individuals understanding of how a circuit functions.

As always, this is a balance. Practical in-class training is expensive and time consuming. Equipment that electricians work with can be extremely expensive. Maintaining it for hundreds of apprentices to terminate/connect/mount can be a nightmare. However, I still believe it is a valuable component that requires more consideration. Perhaps if industry voiced a desire for graduates to have these skills we could start to see a change in how electricians are trained.

From your perspective what is the most important industry trend or direction today or that you see coming in the near future?

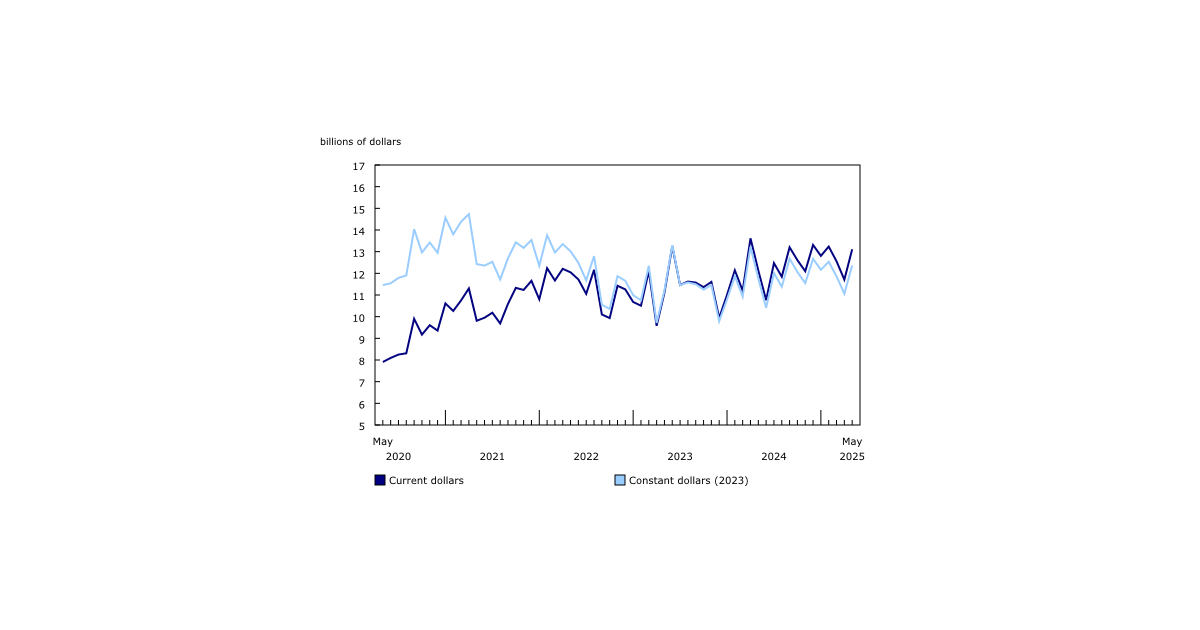

Electricity is the most efficient way to operate industry and vehicles. This is slowly permeating through all areas of our world. This means more electricity will inevitably be required to supply these new loads, and energy efficiency will become a larger component of the electrician’s job. Renewable energy has very recently become the buzzword within Alberta due to government rebates. Solar PV has quickly become an economically viable solution to cut costs on energy consumption and reduce carbon emissions.

The renewable energy field has far-reaching benefits for multitudes of industries going forward. As the cost per ton of carbon emitted increases over the coming years, solar PV will become more of an incentive to large emitters. Trading these renewable credits to offset the carbon emitted will become an important commodity as Canada moves forward. I am interested to see what the long-term impacts will be on large-scale power generation that is not dispatchable. What additional costs will be associated with this move towards renewables? How will these costs be recovered? Areas within the USA have dealt with these realities, with varying success. I am hopeful there will eventually be a balance between “greening the electrical grid” and the costs (long term and short) associated with such an endeavour.

Do you have interesting or unique stories you could share about your experience as an electrical instructor?

I especially enjoy showing demonstrations in class for the assorted topics we discuss. They really make the concepts come alive.

One of my favourites over the years has been a semi-dismantled transformer, 120V primary approximately 1Kva capacity. There are multiple (ungrounded) secondary windings, each constructed of varying loops around the transformer’s core or different AWG sizes. The one which has the best “wow” factor is a single loop of welding cable. When energized, the open circuit secondary voltage developed of 1V can be measured on the cable. When shorted, the current measures upwards of 800A.

I like to have students measure the current with a multimeter, as most have never seen such high values. I then touch the bare copper of the welding cable with my finger, to which nothing occurs. Of course I receive no shock. Nothing occurs due to a number of concepts most experienced electrical professionals fully understand. To an apprentice, this is not an obvious conclusion. Much to my enjoyment, there are typically quite a few students who cringe or flinch as I do this. Assumptions about electricity and danger are brought naturally to the surface of the resulting discussion. Where do shock hazards exist? Is 1V dangerous? Is 800A dangerous?

Demonstrations help make the invisible nature of electricity tangible, and connect reality to the concepts learned in electrical physics.

If you could deliver a message to young individuals considering a career in the electrical industry, what would it be?

In what other trade can you wire a home, work with low voltage smart switching that communicates with your phone, develop the pipe runs for a commercial warehouse, oversee a large project, determine lumen requirements for a given area, reduce a customer’s utility bill by power factor correction or LED replacement, determine the control requirements for an industrial process, read and interpret schematic diagrams, commission flow meters/VFDs/PLCs, estimate jobs, work with explosion-proof equipment, marine applications on wharfs and docks, high-rise offices with large cable feeders, fire alarms, wind power, solar PV, tidal power, energy storage with batteries/flow batteries, donning a 40CAL ARC suit when racking-in a high voltage breaker, climbing into the nacelle of a wind powered generator, maintaining the electrical infrastructure in the oilsands/mine/commercial building/manufacturing plant/floating oilfield platform…

Honestly, I’m getting tired of listing everything. Students getting into this field simply need to know what opportunities are available. If you are willing to try different things, you can live almost anywhere. Electricity is in every city and town, hot or cold climate, inland or coastal. It is a fantastic field to get into.