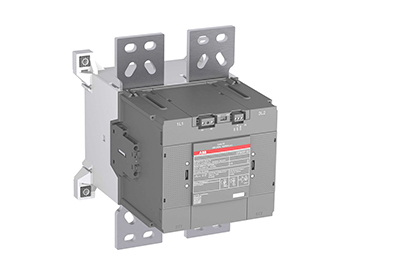

New ABB contactor is first to meet 1500 V DC solar power requirements

May 7, 2019

ABB has launched a new compact, efficient contactor that gives photovoltaic power plants a simple way to introduce 1500 V DC architectures. ABB’s new 1500 V DC GF contactor is the first to meet the IEC’s new dedicated solar power DC-PV3 utilization category and adds another option to the company’s range of 1500 V DC switching solutions.

Giampiero Frisio, head of ABB’s Smart Power business line, said: “The GF contactor is another ABB industry-first that will reduce the time, cost and complexity of new solar installations, and will help make them safer, more reliable and easier to manage remotely. Advances in the hardware that controls, connects and protects photovoltaics are essential for solar power’s continuing development. ABB’s expertise with renewables and power technologies enables us to identify opportunities for innovations that make a real difference to the future of energy.”

By 2020, almost all new utility-scale solar power plants with a capacity of more than 1 MW will be 1500 V DC systems. This higher voltage architecture will make it possible to downsize the electrical infrastructure and will mean significant efficiency gains.

The new ABB GF contactor provides bi-directional switching for loads up to 1050 A and up to 750 V DC per pole, making it possible to control large sections of the power plant. By feeding power into the grid or battery storage systems remotely and automatically, the contactor supports strategies that will improve the energy efficiency of PV installations.

Switching DC in solar inverters differs significantly from standard applications. Solar inverters ramp current up and down instead of breaking electrical arcs, and the DC contactors normally never operate under load. The new GF contactor is the first to meet the DC-PV3’s technical requirements for thermal performance, mechanical switching and for higher breaking capacity in emergency situations.

Frisio added: “This contactor will be a key component in plans to make new solar power plants more efficient to operate and simpler to configure and install. We are already receiving orders and strong interest for this useful new device.”

With one 100…250 V coil that covers all standard network voltage requirements, the configuration process is simpler. The PLC control comes pre-installed as standard and the contactors are designed with wide terminals that can accommodate a variety of different busbar options.

Go HERE for more information

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)