Avoid Electric Shock with This Fault Tree

July 14, 2019

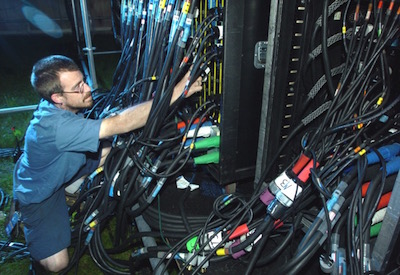

A workshop conducted on behalf of Technical Safety BC (TechSafeBC) to evaluate potential causes of electric shock risks has produced a series of recommendations that address root causes behind the risks. The workshop also produced an electric shock fault tree that can help users understand why electric shock happens and how to prevent it.

The three causal factors that were identified during the sessions include:

• limited oversight of certification requirements and a process to certify electrical workers through a recognized apprenticeship program, which may allow electrical workers and contractors to undertake work for which they lack the appropriate level of knowledge and experience.

• a lack of education and understanding on the part of small or independent contractors, which contribute to issues with corporate resourcing, oversight, and cultural factors

• potential interference with dangerous electrical systems by the general public or untrained workers

These causal factors led to a series of recommendations:

1. Consider developing a program to promote the existing reporting processes for incidents and near misses

2. Consider developing and including material that covers the existing requirements and method for reporting incidents and near misses at the curriculum level for electrical apprentices, and at other opportunities

3. Consider researching and acquiring more external data sources to support targeted risk treatment activities, including:

• hospital data

• workers compensation data

• utility data

• U.S. occupational data/other jurisdictions (i.e. TSSA, NFPA, ESA, UK)

• municipalities

• suppliers/sellers

• IEEE data

• IBEW data

4. Consider undertaking a review of the current curriculum for apprenticeship and certification with the intent to develop content to improve understanding of isolation procedures and verification and testing procedures.

5. Consider creating and promoting an e-learning course to address the same content as in recommendation 4. Consider making this a requirement for FSR renewal, as well as making the content available to apprentices/journey people without FSR certification. Consider partnering with industry associations and trainers to allow the material to be widely disseminated.

6. Consider improving the existing oversight model of electrical contractors and asset owners to close the current gap related to journey people not having workplace-appropriate knowledge or training or not maintaining that training.

7. Consider creating a general awareness campaign to improve public knowledge of shock risks, similar to the “Call before you dig” program. Consider partnering with other organizations to promote the program as widely as possible.

8. Consider creating an orientation program for contractors/asset owners/operators (potentially tied to issuance/renewal of license/operating permit) that addresses the following issues: a. Roles/responsibilities that are associated with each level of authority.

View the full report here

View the electric shock fault tree here

![Guide to the Canadian Electrical Code, Part 1 – 26th Edition[i] – A Road Map: Section 54](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1 – 26th Edition[i] – A Road Map: Section 54](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)