What to Consider When Integrating Digital Estimating into your Business

December 17, 2022

By Melvin Newman – President, PataBid

Digital estimating has been a part of the electrical industry for several decades, starting with early systems in the 1980s that were based on Microsoft DOS. From these early beginnings, digital estimating grew through the 90s and early 2000s into database driven windows applications with thousands of items and assemblies to help electrical estimators bid work faster.

In recent years, digital estimating has somewhat stagnated. The availability of technology in construction has dramatically increased with the advent of Virtual Design Construction (VDC) and other project management technologies becoming the focus of the construction sector. This has led to a lack of focus on the front end of the construction business. However, innovation has started to reach estimating recently, with new platforms being released that allow for a fully digital estimating process that is applicable to small and large contractors alike.

The first key step to implementing a fully digital estimating process is identifying the key stakeholders in the estimating process. People are typically resistant to change and estimators are no different. A large portion of this is due to a lack of trust in new methods and systems until they are proven. No estimator wants to be the “test case” for a new platform. Estimators know that mistakes and miscalculations can severely impact a project and, in the case of a key anchor project, negatively impact the whole company.

Convincing and achieving buy-in about making the switch to digital estimating from the estimators/contractors is critical to any successful software deployment. Depending on the size of the estimating group, it may be beneficial to bring in a subject matter expert with expertise in digital estimating to train the estimators on the new process and systems using a hands-on approach. This is often the best course of action as it enables a close working relationship embedded in the established estimating group. Any bugs or challenges in the new process can be ironed out during the period when the subject matter expert is on premises and helping with the real-world estimates that the team is working on.

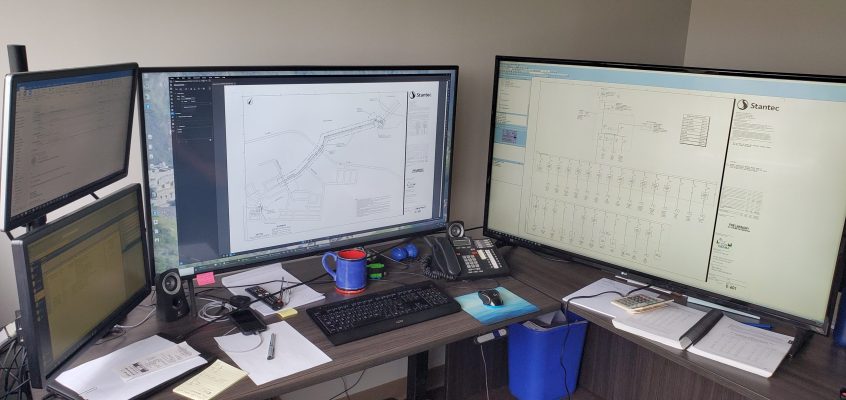

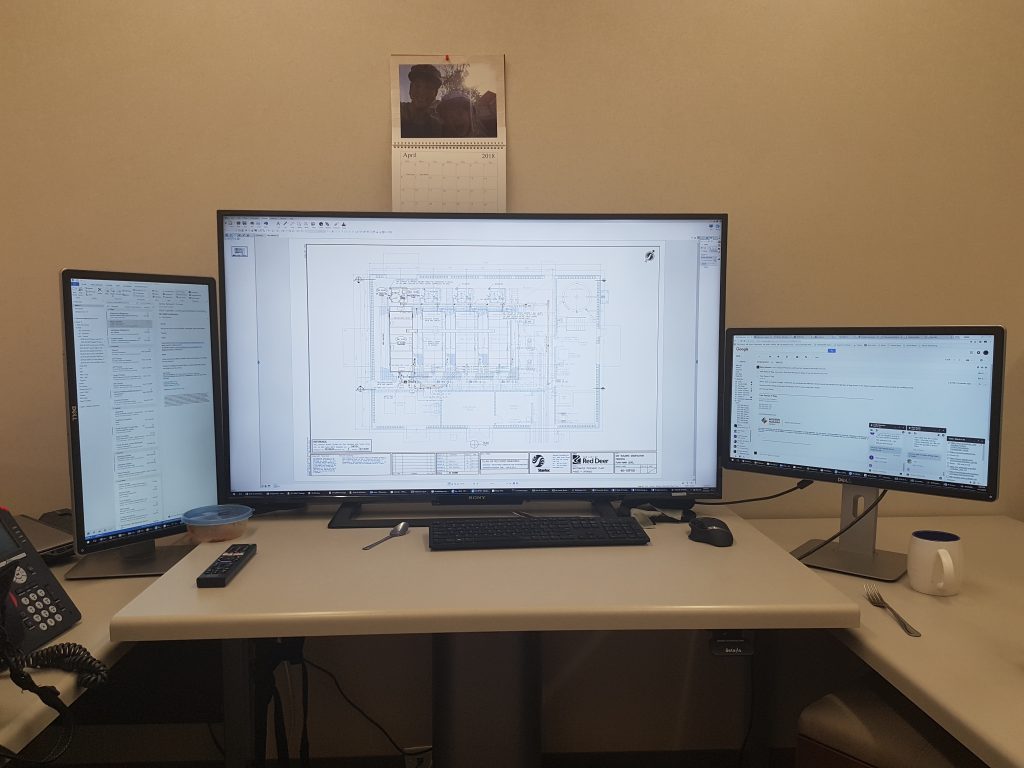

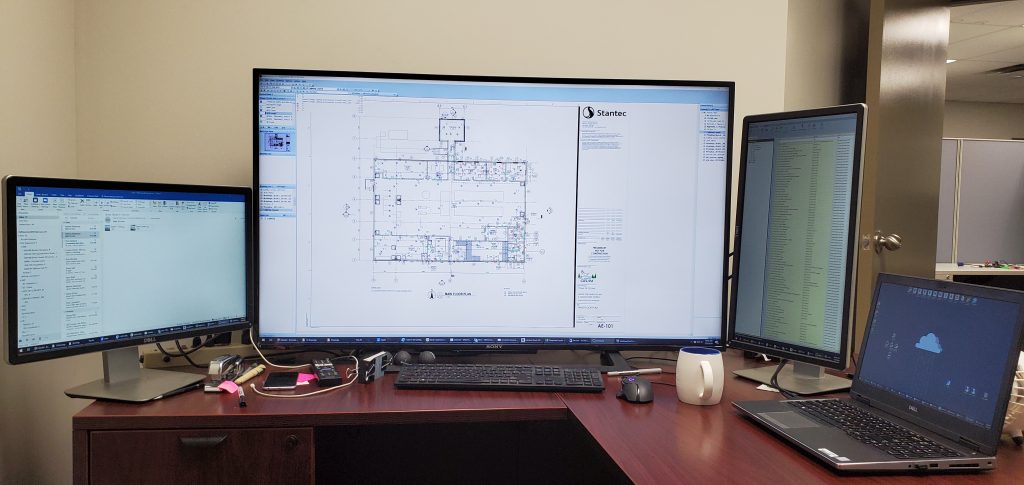

The next step is ergonomics. Properly laying out the digital estimating workstation is absolutely critical to the success of digital estimation. Digital estimating software typically does not require much from a computer. A simple modern business laptop will be more than capable of running any locally installed estimating software. If a cloud based estimating software is used, it gets even easier on the local machine requirements. The key requirement is to have a computer that can handle a 4K UHD screen. Any laptop purchased in the last five years should be capable of handling this output. Even a modern Google Chromebook can typically handle this these days when using cloud-based software.

When setting up a workstation for digital estimation, the key requirement is screen size. While technically a Chromebook or laptop can run estimating software, they do not offer the contractor or estimator the appropriate screen size to estimate with. This is typically the most often overlooked aspect of digital estimating. For a simple comparison, a standard ANSI D page size is 22×34 inches whereas a standard 15” laptop screen is roughly 8×14 inches in size. This means that when trying to view a construction drawing on a laptop the estimator would typically only be able to see a small portion of the overall drawing. This makes estimating very difficult for complex projects as it’s very easy to lose the overall perspective of the drawing. When working on takeoff in a complex electrical room, it would not be possible for an estimator or contractor to see key notes written in the bottom left of the drawing on a laptop screen. It would also be easy to miss the specifications written in the top right of the drawing using a small screen size. Therefore, it is essential that a large screen is used for digital estimation. The minimum recommended screen size would be 48 inches (diagonal). At the common 16:9 ratio of todays screens, this would give dimensions of approximately 24×42 inches. This essentially allows a common ANSI D sized drawing to be viewed on the screen in 1:1 scale with no zooming, panning or manipulation. Using the minimum 4K UHD screen also means that all text and information will be fully readable to the human eye just as a regular drawing would be.

Once the appropriate primary screen has been set up, it may be desirable to set up one or two other screens for use with secondary estimating information. One recommendation is to set up a 27 inch sized monitor in portrait mode beside the main screen. This allows the estimator to put things like specifications on this secondary monitor and view them several pages at a time; ensuring that all relevant estimating information is clearly visible and easily accessible.

With the screens set up, there are a couple of other often overlooked hardware items to take a look at. The keyboard and mouse for a good digital estimating station can have a significant impact on the performance of an estimator. Keyboard and mice accessories from the computer gaming field can provide a significant boost to the productivity of digital takeoff. For example, using a mouse built for playing video games with extra buttons allows the estimator to task those buttons to commonly used features in the estimating platform. Depending on the estimating platform being used, things like items and assemblies can even be “hot-keyed” to the mouse. This can significantly reduce the time that the estimator spends navigating menus and moving the mouse around the large screen real estate.

With the hardware set up and running, the next key decision is what software to select. There are two key categories of software today:

- Locally installed on the estimator’s computer

- Cloud based

Both of these categories have pros and cons associated with them. Locally installed on a computer generally removes the requirement for an internet connection. This allows estimating to be completed in remote locations. However, there are a large number of issues that come with locally installed software, primarily around ensuring that data is securely backed up. Typical laptops and even desktops can be prone to failure and theft. If backups are not properly managed with locally installed software, a large portion of the company’s history and corporate knowledge can be lost relatively easily. Locally installed software is also much more at risk from the rise of “crypto-viruses” and other data theft risks.

Cloud based software such as PataBid’s Quantify Estimating does require an active internet connection to use, however it does not require any locally installed software or maintenance. These days, the internet is generally available almost everywhere on the planet. With new systems like Starlink from SpaceX coming online, even remote “outback” locations can be fully connected with sufficient speed to work with cloud-based applications. Cloud based applications generally have several advantages over local software:

- Cloud based is kept up to date by the host

- Items and assemblies database information can be managed by the host while still offering full customer customization

- Multi-user out of the box, allowing estimators/decision makers to collaborate

- Estimate from anywhere there is a stable internet connection

One more pro-tip to consider when using digital based estimating: the estimator is no longer constrained to any “standard page size.” This can be invaluable on larger projects where a building is broken up into multiple sections in the drawing package. It can be very easy to lose sight of where one section connects to the next and either takeoff too much or too little material. Using freely available open-source applications like Inkscape or Gimp, a segmented drawing package can quickly be combined into one very large drawing. This drawing would be un-printable but fully usable on a large screen digital takeoff. This can provide the estimator with a single overall view of the project and allows the takeoff to be completed much faster as it eliminates the need for switching between drawings. Things like feeder takeoff or piping takeoff can be processed entirely from start to finish with exactly the amount of takeoff needed to complete the project.

Setting up a digital estimating process does not take much investment. It does, however, take some thought and time to develop a digital strategy and bring all stakeholders onboard. Once implemented, the results of digital estimating can be dramatic. Estimates are done to a much higher quality, uniformity and traceability.

For more free resources on digital estimating implementation, check out PataBid’s blog or Youtube channel.

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)