Rigid PVC Conduit vs. ENT in High-Rise and Multi-Use Applications

February 7, 2025

By Phil Crangi

Choosing the right high-rise construction conduit can significantly impact project efficiency and costs. While rigid PVC (Polyvinyl Chloride) conduit may have a lower upfront cost, ENT (Electrical Nonmetallic Tubing) offers more significant advantages due to its long-term labor savings and installation efficiency. ENT and fittings form an integrated system engineered to save electrical contractors time and money.

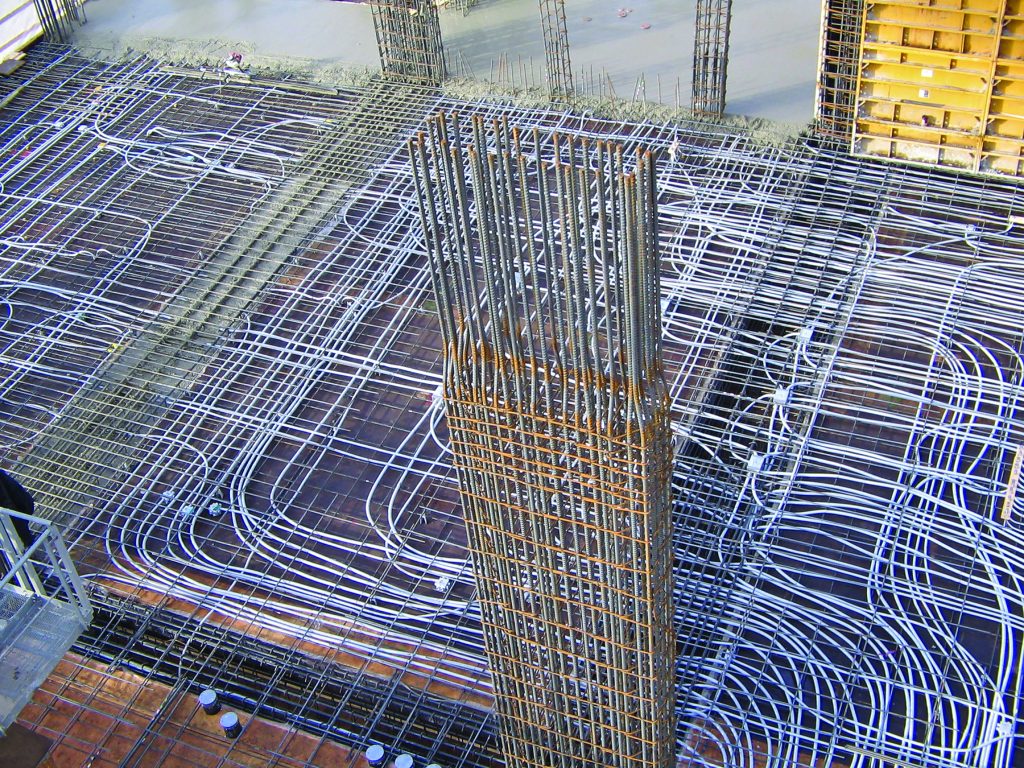

ENT’s lightweight design makes handling and transportation easier, and its snap-in connection method eliminates the need for solvent cement, significantly reducing installation time. Designed to be concrete-tight, ENT is available in flexible, easy-to-transport coils and reels, allowing it to adapt seamlessly to complex layouts. In addition, it can be cut on-site using simple handheld tools.

These features enhance workflows and position ENT as the more practical and effective choice for high-rise applications, establishing a new standard in modern construction.

What are Rigid PVC Conduit and ENT, and how are they used in high-rise construction?

ENT is a flexible, lightweight conduit ideal for embedding in concrete slabs or installing in interior walls of high-rise buildings. It is known for its ease of handling and labor efficiency. In contrast, rigid conduit is a stiff, heavy conduit with solvent-glued joints commonly used for underground and large-diameter applications.

What makes ENT a better choice for high-rise applications?

ENT offers several advantages over rigid PVC conduit:

Ease of transportation: ENT is approximately 50% lighter than rigid PVC conduit and is available in up to 1,500-foot-long reels, reducing transportation and handling challenges and waste.

Simplified installation: ENT’s flexibility eliminates the need for pre-made bends, glue, or additional fittings like elbows, couplings, and adapters. Having fewer connections to make significantly reduces labor-intensive tasks.

Labor savings: ENT can reduce labor costs and installation times by up to 50%, making it a valuable choice for time-sensitive projects with weekly concrete pours.

Concrete tight: Designed for embedding in concrete, ENT is durable and is not prone to cracking.

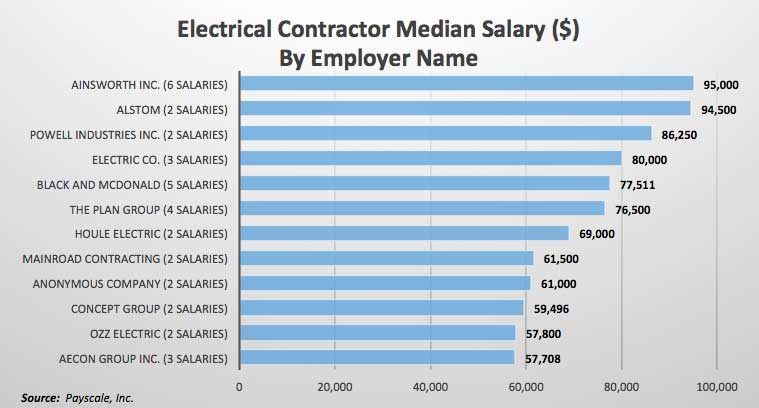

How does the cost of ENT compare to Rigid Conduit?

While the material cost of rigid conduit is 25–35% less, ENT compensates with significant labor savings, as noted above. These savings are especially impactful on labor-intensive, high-rise construction projects. Contractors often find ENT more cost-effective for structures over five stories because the cumulative labor savings will outweigh material costs.

Are there specific use cases where ENT is preferred over Rigid PVC?

ENT is recommended for:

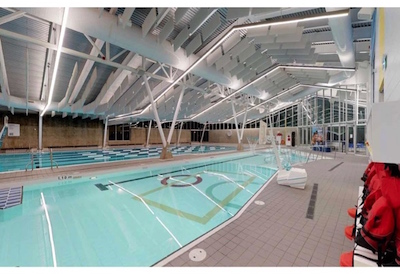

- high-rise buildings exceeding five stories, particularly for embedding in concrete slabs;

- parking decks where concealed conduits enhance visual appeal;

- coastal constructions that require hurricane-proof concrete slabs;

- residential applications for future-proofing walls with flexible wiring options.

What are the durability and environmental considerations for ENT?

Both ENT and rigid conduit meet UL standards for thermal and moisture resistance. When embedded in concrete, ENT’s durability matches PVC. However, ENT cannot be used for direct burial or in areas exposed to ultraviolet light. However, ENT uses less raw material, making it a more sustainable choice for concrete applications.

What challenges do contractors face when adopting ENT?

Their main challenges typically involve a lack of familiarity with ENT and misunderstandings about lower-quality, alternative products. However, we’ve seen that providing education and sharing testimonials from electrical contractors who have successfully switched to ENT can help overcome these concerns.

Why should contractors and engineers choose ENT for their next high-rise project?

ENT offers significant labor savings and straightforward installation, backed by over 25 years of reliable performance. Its complete system includes advanced locking mechanisms designed for long-lasting durability.For contractors who value efficiency and quality, choosing ENT is a practical decision that meets the needs of modern construction projects.

About the author: Phil Crangi is a regional sales manager for IPEX in the United States, based in Tampa, Florida. A native of Pittsburgh, Pennsylvania, Crangi is a 42-year veteran of the electrical industry, having worked at IPEX for the past 13 years. He can be reached via email at phil.crangi@ipexamerica.com.