Effect of Next Generation 100 W Power over Ethernet on RJ45 Connectivity

February 3, 2017

The Institute of Electrical and Electronics Engineers (IEEE) is currently writing the 802.3bt standard, which will double the amount of power delivered to end devices. The current 25.5 W will increase to approximately 71 W, which is an increase of a factor of approximately 3. This new type of Power over Ethernet (PoE) is commonly referred to as PoE++ or 4 Pair PoE (4PPoE), and allows devices such as next generation wireless access points, security cameras with pan, tilt, zoom, and heating elements, and larger displays to operate under the new PoE standard.

There has been significant work by the industry to understand the effect of the next generation PoE systems on cabling. For example, the Telecommunications Industry Association (TIA) document, TSB-184, Guidelines for Supporting Power Delivery Over Balanced Twisted-Pair Cabling provides guidance for installing cables that run PoE with currents up to 600 mA on two pairs. This TSB document will soon be upgraded to TSB-184-A to provide guidance specific to PoE++ which is up to 960 mA on four pairs. These documents recommend that a bundle of cables should not exceed a 15oC temperature rise within the center of the bundle. This temperature rise depends on the

- size of bundle

- current running through the wire pairs and number of energized pairs

- cable wire gauge and construction

However, little work has been performed to illustrate the effect of this new standard on the connectivity.

As shown in Table 1, the new standard requires an increase in current of approximately 360 mA. It also requires the use of all four pairs, as compared to typically using only two of the four pairs.

Cable manufacturers will provide users with information about the maximum bundle size that can meet the 15-degree temperature rise limit recommended in the TIA TSB-184 document. When planning for higher-power PoE, the proper equation to use is: cable temperature rating is less than or equal to the ambient temperature plus 15.

Regarding PoE and PoE Plus, Category 5e, 6, and 6A cables all comply with TSB-184’s 15-degree maximum temperature rise when tested in bundles of 100 cables. However, during testing of 802.3bt pre-standard technology, only Category 6A cables stayed within the 15-degree recommendation for these large bundles. A couple recommendations to take away from these test findings are that Category 5e and 6 runs should be assembled in bundles of fewer than 100 cables; and Category 6A cabling is recommended for running PoE++.

The purpose of this paper is to explain the effect the new 802.3bt standard running the highest Type 4 power will have on connectivity, specifically the Panduit TG style jacks.

Connectors in PoE++ system

Heat rise and cable arcing could have harmful effects on cabling system performance when those cables are carrying 100 W PoE. Significant temperature rise will increase cable insertion loss and may create bit errors, however, an extreme temperature increase above the cable operating range can damage the cable. There are two concerns with connectivity supporting PoE systems: arcing (sparks) and heat.

Arcing

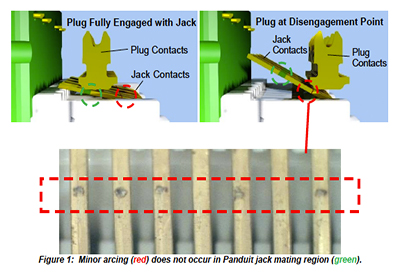

When a twisted-pair channel is running PoE and the plug is removed from a jack, an arc (spark) will occur between the plug contacts and the jack contacts at the point of disengagement. This is normal and happens in all PoE systems. However, the increase in current, which can lead to more severe carbon scoring, is a new concern involving PoE++. Carbon scoring can interfere with the connection between the plug and jack, causing the link to not function if there is too much carbon build up.

There are two methods of mitigation to combat this effect. One method is to ensure that the disengagement point of the plug (red) is different than the plug and jack at the engaged mating location (green) (Figure 1). The other mitigation procedure is to ensure that there is sufficient contact normal force on the jack. Contact normal force refers to the amount of force the jack contacts push on the plug as it is inserted. A Panduit jack is rated to 100g normal force. This ensures that as the plug is inserted, there is sufficient abrasion of the plug to remove any carbon scoring on it.

Panduit jacks have been validated to meet the new PoE++ Type 4 power and current levels with respect to carbon scoring. For information on engaging and separating connectors under electrical load, refer to Standard IEC 60512-99-001. Panduit jack and plug connectors are verified and rated to 2500 cycles of plugging and unplugging with live PoE++ Type 4 running, well beyond the industry standard of 750 cycles. This was verified by measuring the contact resistance (DC resistance test) before and after the cycling, to ensure there was no substantial change in the resistance, as well as ensuring that the connectors still have sufficient normal force after the 2500 cycles are complete. The plug interface contacts on Panduit jacks are unique in how they utilize a cantilevered design wrapping around a front mandrel, which is a design that is optimal for repeated plug insertions.

Heat

The second effect of PoE++ is heat. Heat to a connector can come from two sources:

1) heat from the cable transferring to the jack

2) heat due to the current from PoE running through the jack

Panduit tested this in the configuration shown in Figure 2. Panduit heated a cable in a chamber up to 60oC, and passed different current levels through the cabling and connectors corresponding to the different PoE current and power levels.

The results of this test are shown in Figure 3. The x-axis represents the temperature rise of the cable in the bundle at Location A over the ambient temperature. The y-axis represents the temperature rise of the jack at Location B over ambient.

This indicates the following:

- the temperature of the cable in the bundle had almost no impact on the temperature of the jack

- the amount of current in the system had an impact on the jack. At PoE++ Type 4 levels with the current at 1 A per pair, the temperature rise was approximately 5oC

- the industry standard operating temperature for connectors has been -10oC to 60oC, which assumes that a connector can operate in a 60oC ambient temperature. These data show that with the new PoE++ standard, the jack should be rated to 65oC to operate in a 60oC ambient temperature

- to meet the demanding needs of the new PoE++ standard, Panduit has updated its connectors to have a new operating temperature of -10oC to 65oC. Panduit has validated this design through extensive temperature life testing.

Conclusion

The new IEEE standard offers a compelling solution for providing much needed power to end devices. Increasing the amount of current and the number of pairs running PoE from two to all four offers expanded capabilities, but also has the following effects on connectivity:

- increased carbon scoring at the plug disengagement point

- approximately a 5°C rise in temperature above ambient for the connector

To confirm the connectivity can handle PoE++:

- ensure the connector can meet its cycle rating if that channel is running PoE per IEC 60512-99-001; Panduit connectors are rated for 2500 cycles with PoE++, well beyond the industry norm of 750 cycles

- to account for the temperature rise from PoE++, use 65oC rated connectivity

Running 100 W per wire over twisted-pair structured technology makes infrastructure choice critical. Therefore, to adequately manage the effects of 802.3bt, Panduit recommends there should be a clear understanding of the following power considerations:

- ensure ambient temperature plus cable bundle temperature rise does not exceed cable operating temperature

- all cable gauge sizes still work, but bundle sizes are more limited for smaller gauges

- ensure connectivity can meet applicable standards to prevent arcing damage to critical mating area

- choose cable with higher operating temperature, if needed

- limit bundle sizes to ensure temperature rise is 15° or lower

- category 6A cabling is recommended for new installations for future proofing

The new 802.3bt standard will guide the installation of powered devices, power sourcing equipment, and cabling systems. Panduit is an industry leader in the study of the effects of PoE on both the cabling and connectivity. This knowledge has been incorporated into product design. Panduit’s Category 6A system offers customers the best-performing PoE system in the industry.

References

- TIA-TSB-184, Guidelines for Supporting Power Delivery Over Balanced Twisted-Pair Cabling: http://blog.siemon.com/standards/tsb-184-power-delivery-over-twisted-pair-cabling

- IEEE P802.3btTM /D1.0, (Amendment of IEEE Std. 802.3™-2012), Draft Standard for Ethernet Amendment: Physical Layer and Management Parameters for DTE Power via MDI over 4-Pair, 29th May 2015

This article was previously published as a white paper by Panduit Corp.

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)