Industrial Wiring Devices: A Brief Intro and How to Choose Them

June 9, 2025

Introduction:

With the multitude of options on the market, it can be difficult to decide whether you need a pin and sleeve wiring device or a plug and connector in your industrial plant or facility. You might find your head swirling with thoughts about which option is best. Or you may not even know which one you need where. You do know you want to ensure maximum electrical protection, and you can’t have machines shut down due to moisture, dust or contamination that weasels its way into your system. But what’s the difference between a pin and sleeve vs. a plug and connector? And once you decide on that, how do you narrow down your choices from there?

How can you know exactly what you need?

It can be tempting to go to the extremes, either settling on the least expensive option to free up some room in the budget or opting for the maximum level of protection “just in case.” However, there’s a balance involved with selecting these electrical devices, and it has everything to do with where they will be used.

In short, it depends on the application.

What you choose depends highly on the where and what, and it also means you need to think about appropriate amperage, voltage, environmental factors and ratings.

But first, you need to understand the difference between them.

What’s a Pin and Sleeve Device?

Let’s start with the highest level of safety and work our way down. That brings us to pin and sleeve electrical devices.

For particularly intense environments, pin-and-sleeve devices are an excellent option for electrical connections that require extra security. They are ideal for many industrial plant applications because they can handle high electrical currents running between large pieces of equipment and receptacles, especially in wet or corrosive environments. They are rated at high amperages, normally 60A to 200A, and provide protection against many elements, including chemicals, dirt, dust and moisture.

When it comes to pin and sleeve, you are often dealing with the IEC, which is an organization that sets the standards for many electrical system installations throughout the world. IEC 60309 is the relevant standard for pin and sleeve devices in industrial settings at high voltages and amperages, and it involves five sub-standards. The first two are the most widely adopted, and they basically ensure safety requirements and that the plugs and holes match up.

What’s interesting about pin and sleeve devices and the IEC 60309 is that this enables many pin and sleeve devices to be interchangeable. As long as they are properly mated, which is organized through a color system based on voltage, you can use different pin and sleeve plugs and connectors.

Now that we’ve tossed out “plug and connector” with pin and sleeve, let’s clarify that.

Pin and sleeve devices are offered as plugs and connectors. The male plug has a certain amount of pins that match the female connector. This is why they are designated “pin and sleeve,” despite the fact that they are technically also plugs and connectors. In addition, there are also pin and sleeve receptacles and inlets. Just remember that these are your high amperages, high voltage devices that provide the most safety. This is what you choose when you want to bring in the big guns.

PIN AND SLEEVE WIRING DEVICES COME IN THREE TYPES:

- SPLASHPROOF

- WATER-TIGHT

- SWITCH-RATED

We’re going to dig deeper into plugs and connectors, describing the differences between splashproof and watertight designations, so just keep these options in mind for now. The main thing to remember is splashing is slightly different from watertight, which means it can withstand temporary immersion. With splashing, you are talking about a less intense contact with water. Think of a watch. Many can handle it if you wash your hands, but that’s very different from swimming laps with it on.

When it comes to switch-rated pin and sleeve devices, these types ensure there is no arcing. Technically, these are a combination of pin and sleeve with a mechanism that allows for disconnecting under load. They are ideal for high arc risk and environments with frequent washdowns or heavy water presence.

Ok, so what about Plugs and Connectors?

Like we mentioned earlier, pin and sleeve devices can technically also be plugs and connectors – but they are in a class of their own, designated as such because they can handle intense applications. On the other hand, there are plugs and connectors. Essentially, these are doing the same thing (providing an electrical connection), and they are a great option for industrial applications as well. The difference has much to do with safety, but that is not to say that plugs and connectors are not safe.

Plugs and connectors are very safe with ratings that designate the degree of safety for each type (here’s your first introduction to the IP rating). In fact, you may not need pin and sleeve devices at all in your plant. They could be overkill – and they’re more expensive. Plugs and connectors can handle a wide variety of industrial applications just fine.

Plugs and Connectors come in a variety of options that you will need to explore & determine before diving into the IP Rating.

To begin, you’ll want to decide on the amperage and voltage that fits your specific needs best.

In addition, you’ll need to choose either a straight blade or locking type.

- Locking plugs and connectors are ideal for situations where you do not want the power to disconnect, such as power generators, as the locking mechanism latches them together and prevents unplugging and power disconnection.

- Straight blade plugs and connectors, on the other hand, do not offer this locking mechanism but are useful for a variety of applications where that is not a top concern.

Once you’ve determined the appropriate amperage, voltage and level of safety assurance you need, you can begin to delve into the IP rating to make your final decisions on plugs and connectors.

What’s the IP Rating?

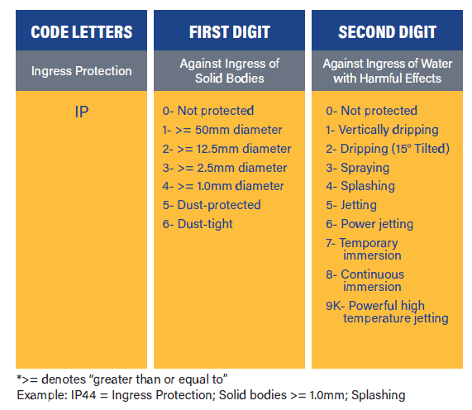

Electrical equipment, including industrial plugs and connectors, are rated using an international system called the International Protection (IP) Rating. It is also referred to as the Ingress Protection Rating. When examining an electrical device’s IP rating, you are evaluating a system of two digits: the higher the digit, the greater the degree of protection. This applies to both digits in the system and is specific to properly installed equipment only.

When something is rated 0 and “not protected,” there is no protection against contact and ingress of foreign objects. As you move up with the first digit, the size of the objects it protects against decreases. For example, a first digit of 1 provides protection against a solid greater than or equal to 50mm in diameter, which is roughly equivalent to accidental contact with the back of your hand. When you get up to 5, you’re looking at what’s called “dust-protected,” meaning that the device is protected against all contact and, while dust ingress is not 100% prevented, it can’t enter in a large enough quantity to cause damage to or shut down the equipment. On the other hand, a dust-tight device (6) would not allow any dust to enter.

Likewise, the second digit denotes similar protection only specific to liquids. For instance, a 0 here is also not protected at all. As you move up with the second digit, the type of liquid exposure rises in intensity. There are specific definitions for each type of liquid exposure. Dripping water is defined as water drops that fall vertically down upon an enclosure either laying flat (1) or when it’s tilted at an angle up to 15° (2). Spraying water (3) can be projected to an enclosure at any angle up to 60°, while splashing water (4) can come from any direction at all. Water jetting (5) denotes a projection from a 6.3mm nozzle from any direction, but power jetting (6) is considered a projection from a much larger, 12.5mm nozzle from any direction. Additionally, both types of immersion have specific measurements of pressure, time and distance. For example, temporary immersion (7) only applies to submersion up to 1 meter, while continuous immersion (8) applies to distances beyond 1 meter.

BUT FOR INDUSTRIAL APPLICATIONS, THERE ARE REALLY JUST FOUR SPECIFIC TYPES OF PLUGS AND CONNECTORS YOU SHOULD CONSIDER

- DUST-TIGHT

- WATERTIGHT

- BUILT-IN ANTIMICROBIAL PRESERVATIVE PROTECTION

- GROUND CONTINUITY MONITORING (GCM)

Dust-Tight Plugs and Connectors

Dust-tight plugs and connectors are rugged options for both commercial and light industrial applications, such as dry outdoor use with shop tools and extension cords.

The dust-tight body is made of rubber, providing resistance to impacts, oils, chemicals, heat and weather. Many dusttight plugs and connectors are constructed with floating, nickelplated blades that allow for self-alignment with contacts and provide long-lasting corrosion resistance. These items do not allow any dust ingress, making them a superior choice for many light industrial applications.

PERFECT FOR:

- Dry outdoor environments

- Shop tools

- Extension cords

Watertight Plugs and Connectors

Watertight plugs and connectors are not only dust-tight, but they are also rated as watertight with an IP67 rating, meaning they not only completely protect against dust ingress but can also withstand temporary immersion. In fact, these devices feature multiple seals for maximum

protection and are rated for 1,500 psi high-pressure hosedowns, a common occurrence in many industrial environments. The thermoplastic elastomer (TPV) rubber construction is incredibly sturdy and provides resistance to impacts, oils, chemicals, heat and weather. They also feature

corrosion-resistant nickel-plated blades. These devices are appropriate for both commercial and industrial applications, particularly for wet environments indoors and out.

PERFECT FOR:

- Wet indoor or outdoor environments

- Machines

- Shop tools

- Extension cords

Plugs and Connectors with built-in Antimicrobial Preservative Protection

For protection against microbial degradation, plugs and connectors with built-in antimicrobial preservatives are an excellent choice with an IP rating of IP65, 66, 67 and 69.

These devices feature antimicrobial preservative additives embedded directly into the polymer components. The additives are gradually and continuously released to the surface, inhibiting the growth of microorganisms that can cause degradation of the components and providing long lasting protection to preserve the integrity of the product.

Additionally, plugs with built-in antimicrobial preservative protection are also dust-tight, watertight and constructed of TPV rubber. They are also rated for 1,500 psi high-pressure hosedowns and do not allow any dust particles to enter. In this way, the combination of all three defensive features makes these devices a triple threat against the elements in many light industrial applications.

Plugs and connectors with built-in antimicrobial preservative protection are incredibly powerful, protective electrical devices for harsh industrial environments like food and beverage processing plants, where the equipment is not only subject to frequent hosedowns but also needs to maintain cleanliness and avoid contamination. Independent testing proves the ability of these devices to inhibit the growth of microorganisms that can cause product degradation. This product does not protect users or others against bacteria, viruses, germs or other disease organisms

PERFECT FOR:

- Wet indoor & outdoor environments

- Food & Beverage processing facilities

- Machines

- Shop tools

- Extension cords

GCM Plugs and Connectors

Of all the potential safety hazards, the proper grounding of electrical equipment always seems to be near the top of the list. In fact, electrical grounding and ground-fault issues are constantly among the most commonly cited OSHA violations, year after year.

GCM plugs and connectors will monitor your upstream circuit for improper grounding and multiple mis-wire conditions. GCM technology allows the plug or connector to look upstream, or toward the panel.

Every GCM plug and connector is equipped with two (2) sets of red and green LEDs to help indicate multiple potentially hazardous wiring conditions. The LEDs have been oriented approximately 180° apart so they’re visible from any angle. This setup, using both a GCM plug and connector, will also be very helpful in troubleshooting. A green light on the plug and a red light on the connector tells you that your problem exists within the cordset. However, red lights on both ends indicate a definite problem behind the wall, as well as a potential problem with the cordset.

GCM plugs and connectors are available in straight blade or locking versions with watertight models in both categories.

PERFECT FOR:

- Shop tools

- Extension cords

- Receptacle test areas

50A Turnlok®, California Standard and Corrosion-Resistant Plugs and Connectors

When it comes to temporary power applications, every connection must count to ensure consistent, reliable and safe power delivery.

50A Plugs and Connectors are designed specifically for these environments. Engineered to make installations faster, safer and more dependable, these devices feature a revolutionary push, twist and lock design that eliminates the need for time-consuming threading. The back body easily slides onto the device and locks in place with a quarter twist.

Crafted from industrial-strength brass alloy for excellent conductivity and resistance to heat rise, these devices feature a Nylon 66 shell material that is impact and corrosion-resistant, ensuring a high performance in even the toughest temporary power conditions.

Each 50A Plug and Connector features an adjustable cord clamp strategically located outside the back body to accommodate various cord sizes. The device’s same-plane hex terminations make every termination faster and safer while the integral flexible rubber cord grommet provides protection from oils, water or chips entering the wiring chamber.

PERFECT FOR:

- Construction sites

- Outdoor events

- Entertainment venues

- Data centers

- Emergency response & disaster relief operations

IN CONCLUSION…

In order to select the appropriate plug and connector for your industrial use, it’s important to understand the IP rating and consider the application. Once you do, you’ll be able to make the best

decision for your facility, which may be a combination of several different types for different areas. In that way, you can provide the right level of protection and rest easy with your choice of well-suited, dependable electrical devices.

Go HERE for more information on Legrand Plugs and Connectors

Go HERE for more information on Legrand’s Electrical Solutions for Industrial Applications

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)