S&C Designs Shelter-Aisle Style Custom Metal-Enclosed Switchgear for Airport

September 26, 2025

S&C Featured Solution: Custom Metal-Enclosed Switchgear

Customer Challenge

A major airport needed to renovate one of the switch houses serving runway loads. For increased reliability, the existing manually operated switchgear in the building would be replaced with automatic source-transfer switchgear.

Since there was no room for the replacement gear inside the switch house, it would need to be located outside, in a self-contained enclosure. But there was concern for the time required in setting up a crane airside and installing the gear, one bay at a time.

Factory-assembly of the gear would be essential.

S&C Solution

S&C designed a seven-bay lineup of Custom Metal-Enclosed Switchgear for the application. The gear is rated 4.16 kV nominal, 60 kV BIL, 270 MVA short-circuit.

The 11-gauge sheltered-aisle type switchgear resembles a walk-in room. It includes three 1200-ampere power-operated Alduti-Rupter® Switches on the sources and bus tie, and four 600-ampere manually operated Alduti-Rupter Switches with Type SM-5S Power Fuses on the feeders. A grounding switch is provided for each Alduti-Rupter Switch.

| Exterior view of S&C’s seven-bay lineup of Custom Metal-Enclosed Switchgear. | Inside view of the airport seven-bay lineup. |

The switchgear is fitted with mechanical non-paralleling interlocks on the source switches, and between the source and feeder switches and their grounding switches.

Blown fuse indicators are provided in the feeder bays. Current transformers in the feeder bays are connected to digital meters with event recording capability and waveform capture. A small UPS powers the meters in the event utility service is lost.

The walk-in aisle is equipped with interior and exit lights, GFI outlet, fan for air circulation, panic-barequipped doors, and rubber floor matting. Meter pans are located on the wall, across the aisle from the operator bay. The exterior of the gear is equipped with high-pressure sodium lights.

Results

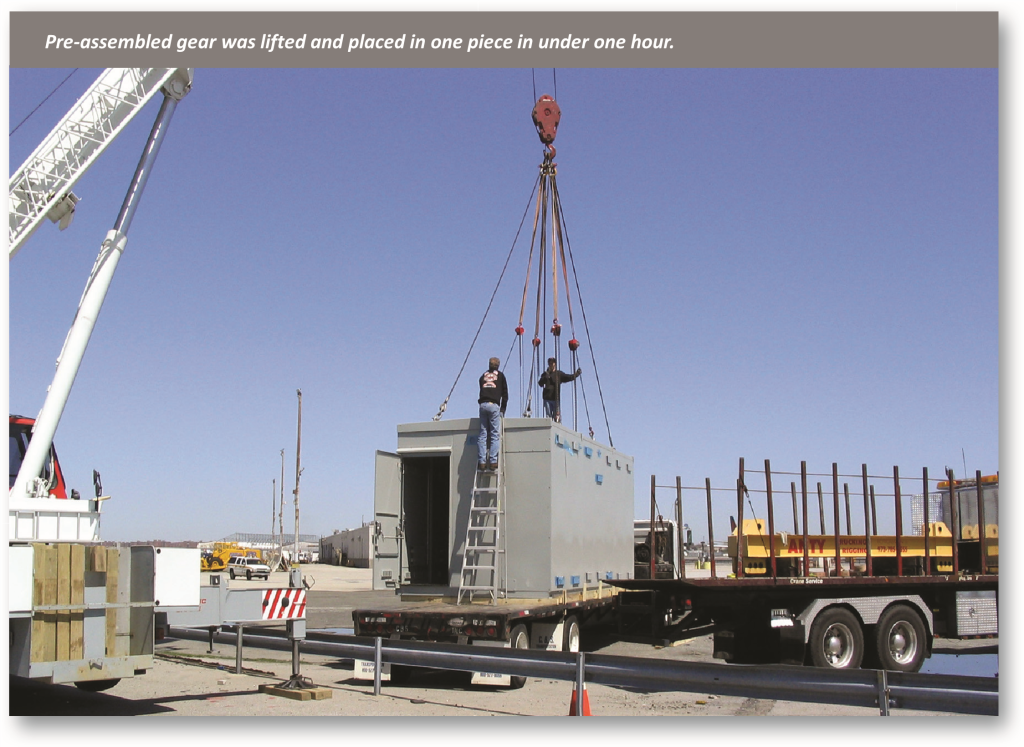

To minimize field installation time, S&C completely assembled, wired, and tested the switchgear and its controls. A special truck was brought in to transport the assembly from the factory to the airport.

On the day the contractor was ready to install it, the switchgear was brought into the area at 2:30 am. Runway clearance for the crane and the gear was obtained at 7:00 am. The assembly was lifted in one piece and placed on its pad by 8:00 am. The airport was extremely pleased with the ease with which the gear was installed and commissioned.

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2-768x432.png)

![Guide to the Canadian Electrical Code, Part 1[i], 26th Edition– A Road Map: Section 56](https://electricalindustry.ca/wp-content/uploads/2022/11/Guide-CE-Code-2.png)